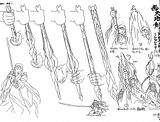

Hello! I'm currently trying to work out a plan for building this "lightsaber"

My main problem is the thin width of the upper hilt, which is a rounded rectangle shape. It seems that the smallest heatsink (1" OD) for an LED would probably be a bit too wide for width, so I devised a design plan below that uses EL wire (which probably isn't the best). In short, (1)Would the plan below be feasible? (2)Is the parts list at the very bottom missing things/incorrect? (3)Is there a better electronics option that could work with such a awkwardly thin hilt? Thanks!

Parts list

-----------

3/4" polycarbonate tube (40" long)

3/4" blade tip

1/2" OD, 3/8" ID polyethylene tube (40" long)

2 80" long 2.6mm EL wires connected to a Y connector, 30" extension cord, and battery pack (buying pre-soldered)

8-32 x 3/8" Retention screw

Reply With Quote

Reply With Quote

Bookmarks