Ok, i posted pics of a few sabers in the works (http://forums.thecustomsabershop.com...ead.php?t=8545 , thread)and got multiple requests to elaborate on the claws on the larger of the two sabers. So here goes on how they were made.

Tools: drill press, drill bits, dremel, dremel drum sanding head, center punch, tubing cutter.

First you need some: 1/2OD aluminum tubing

3/8"x0.171"x1/2" nylon spacers

M4x.7x1/2 (metric) socket head screws

Spikes of your choice with a round 3/8" base

( i used 4 2" cone spikes)

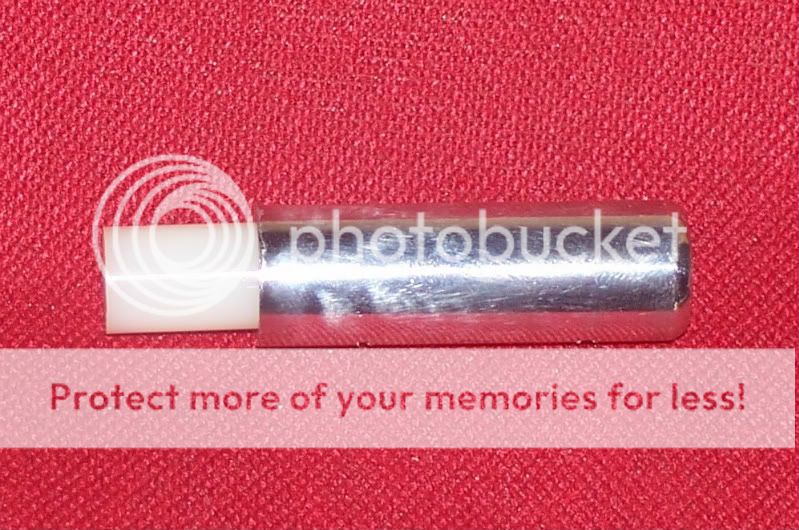

Now i cut 4 1&1/2" pieces of tubing with the tube cutter.(reusing image here)

Next take the screw head and measure with a caliper then find a drill bit that matches the diameter. Then clamp the nylon spacer in to a drill press vice or what ever clamp you have to hold it. Be careful here as the clamp will deform the spacer on the end it holds. then drill into the spacer widening the center hole until you are about 1/8" to 1/4" away from the opposite end. Best to mark your drill bit with a bit of masking tape to ensure an accurite drilling on all spacers.

Once you have drilled all the spacers out insert the screws until the stick out the opposite side.

Next insert the spacer and screw into the tubing piece until the screw sticks out the end.

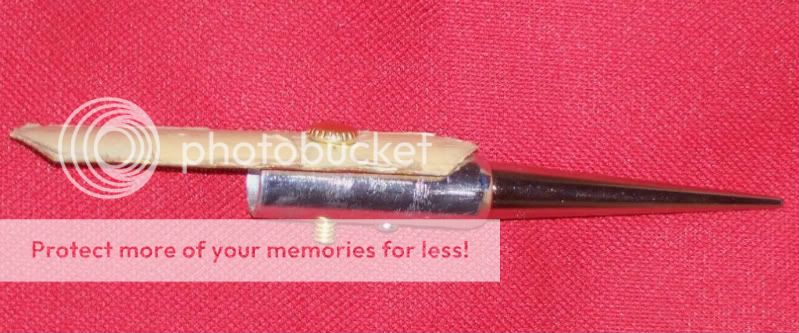

Now decide how you want the base of the spike to line up with the end of the tubing it can be flush or slightly recessed or what ever i went with a slight made 1/16" recess. then hopefully if you have built sabers before or if this is your first one and you are using a hasbro sound board from a saber, save the screws from the saber as they are a perfect thread for biting into the nylon spacer as a lock screw. by drilling into the tubing and spacer with a bit the size of the core of the screw ( found by examining bits and the screw side by side carefully). Then remove he spacer and drill the hole in the tubing large enough to allow the screw to slide through(use caliper to measure thread and core of screw together and find drill bit). then reinsert spacer into tubing and insert screw and it should look like this. (This pic also shows the hole i drilled for the 8-32 screw which holds the claw to the blade holder.)

Now just screw your spike to the end of it and it is ready to go, also if you want it to sit better on the blade holder you might want to use a dremel sanding drum and put an elongated notch in the side you intend to touch the holder as this produces a nice flush fit. And here in the complete claw. ( the piece with tape on it is actually one of the cut outs from the overlay of the saber i though they might ad a little something to the claws use your imagination.)

Now for the blade holder, here i drilled two holes one threaded for the 8-32 screw that holds the claw to the blade holder the other is a recess hole(which is hard to see in the picture kind of blurry sorry) for the head of the lock screw which is hidden facing the holder.

And here is the end result.

Hope this works for every one. Let me know if you have any questions.

Reply With Quote

Reply With Quote

Bookmarks