Well here we go, I sketched the basic idea and have decided to go with a sink tube for the hilts structure. I plan on cutting a custom emitter and making an aluminum sleeve on the end, just in case I wanna hit someone with the end of it, plus I think it'll look sweet.

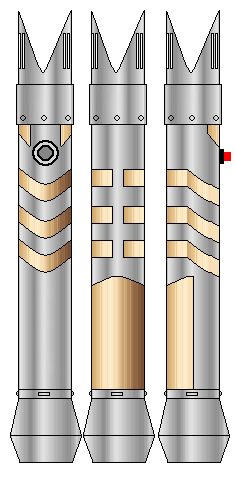

Saber Concept:

http://img401.imageshack.us/img401/9...conceptoe0.jpg

Picture is a little big....

Also I erased the rings on the front view to see what it would look like, I also have no idea hot the sink tube adapter would fit so I drew different possibilities of it.

Some things im still thinking about:

I think the length im shooting for is 9.5 in. Too small? Any problems I may encounter?

Debating on whether or not to have the rubber ring grips and the ribbed brass plate.

Also considering eventually making a twin for a staff style saber. If I did, does anyone know any alternatives to just screwing them together? Kinda want a quick and effective way to connect them and disconnect.

Not exactly sure on the pommel, I have 2 designs on there. Dont know which one would look better.

I really need all the input I can get before I actually start cutting and ordering parts. I wanna make my personal saber pretty sweet and would appreciate creative criticism/ideas/suggestions you know?

-EDIT Oh ya I still havent decided on the hilts color either. Im pretty bad with that so suggestions are welcome!

Thanks!

Reply With Quote

Reply With Quote

Bookmarks