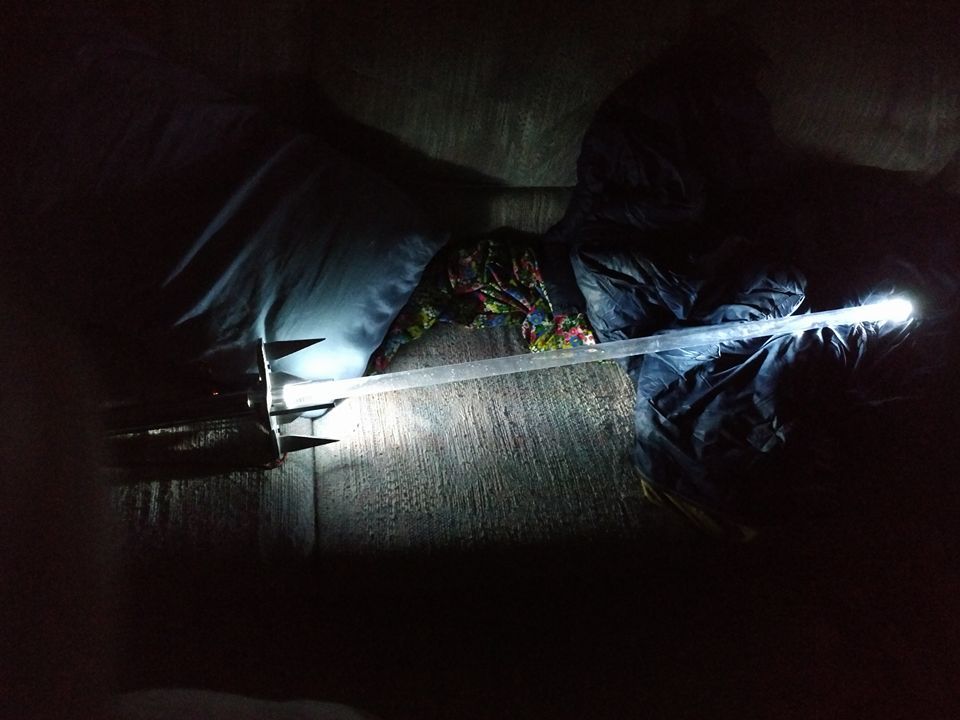

Well I have taken my first steps into a larger world. You see in the photos the beginning stages of a sink tube saber with something special on it. A guard and quite a large one if I do say so myself not to mention the claws. Almost all lightsabers don't have guards which is understandable. I'll just say mine is made of Mandalorian Iron even though it is aluminum.

I work in a factory so that's how I managed to get the unique shapes. They did mess up cutting the thing as you can probably see. I don't mind so much as I was going for an ancient beat up saber look. Rather neat what happened to the cord when I tightened it on the one end. Not sure how that happened.

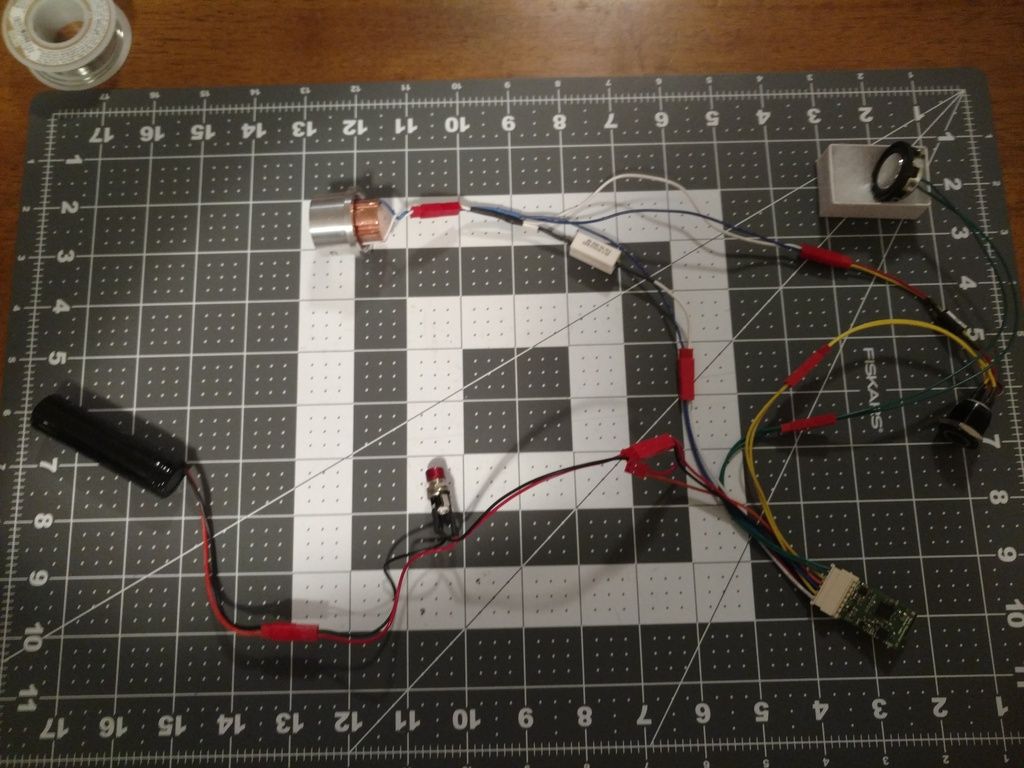

From here I need to figure out how to secure the cord as it still moves around, super glue perhaps? Then I need to get a shopping list together so I can illuminate this thing with MWS, figure out how I want to engrave the guard and claws and practice, practice, practice the engraving before hand so I don't mess it up. From there I will see where this hobby takes me.

Reply With Quote

Reply With Quote

Bookmarks