-

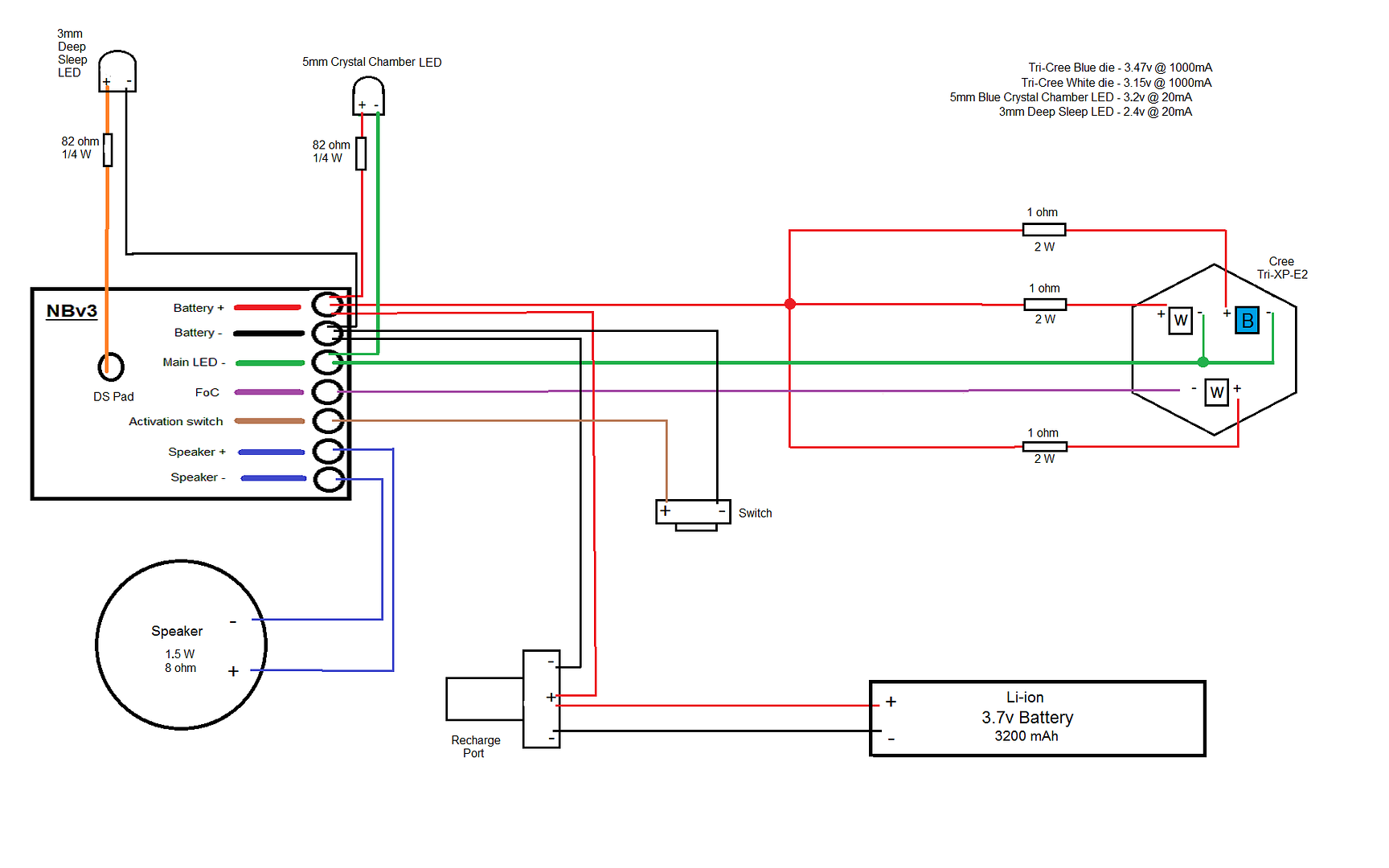

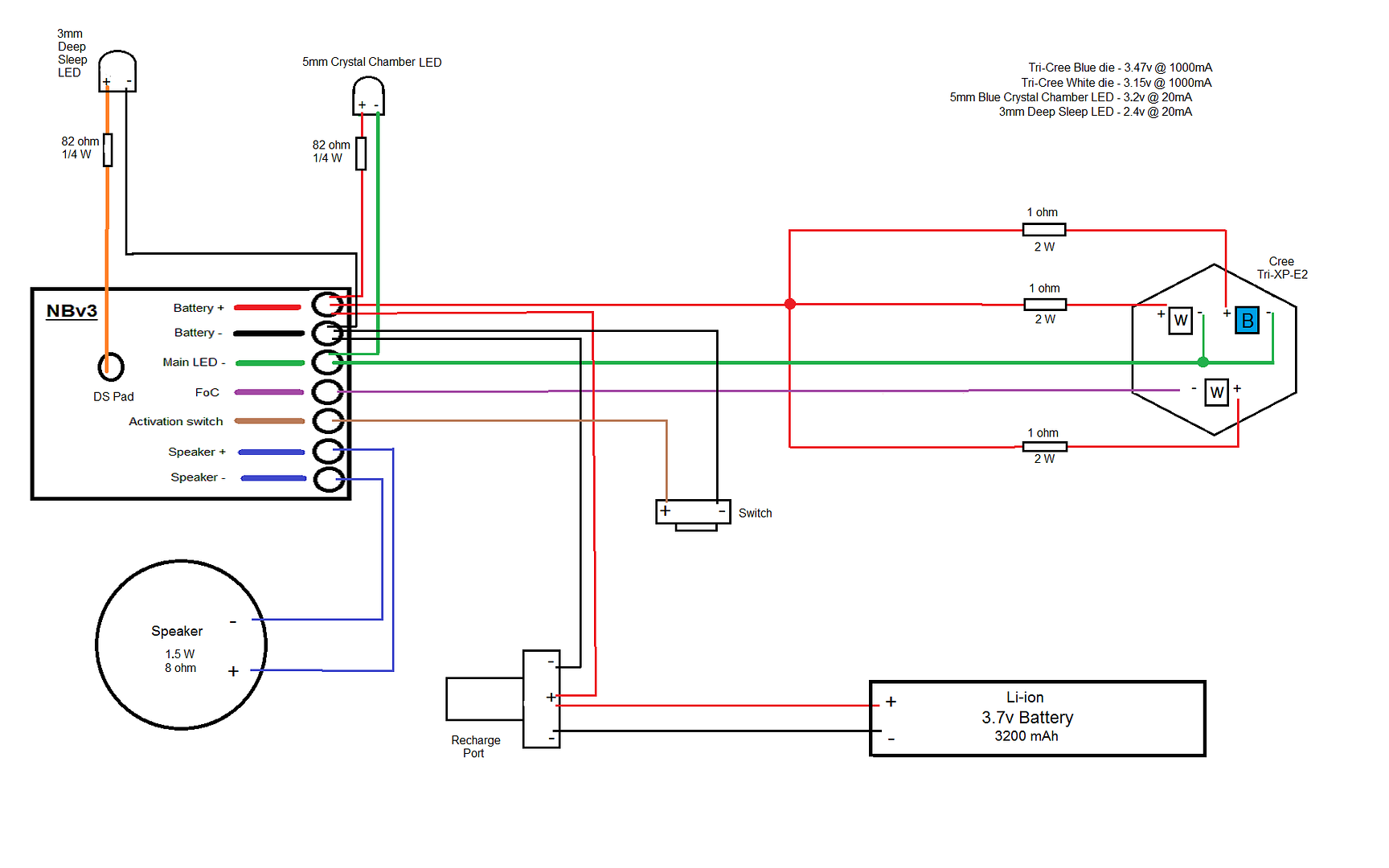

Ok. So I changed all the resistors for the Tri-Cree to 1ohm-2W.

The deep sleep LED calculated to 82ohm-1/8W, the closest the shop here offers is 82ohm-1/4W. Am I correct in assuming that using a larger wattage will just allow the resistor to dissipate more heat (and take up more space) without affecting the brightness?

Also, my crystal chamber LED calculated to 47ohm-1/8W, the closest available being 82ohm-1/4W. I think I could go with this, right? Will increasing the resistance that much really dim the LED a lot? Or is that difference negligible?

Here is an updated drawing in case anybody new reads this for the first time.

-

Youngling

You're essentially correct. The wattage rating of resistors indicates the amount of power they are capable of dissipating before they burn out. Your crystal chamber shouldn't be affected much by the increased resistance.

-

Another question to ask , what is a good temperature setting for my soldering iron when soldering to the pads on the board?

-

Youngling

Well, I normally recommend 700?F as a pretty good starting temp. That's hot enough to melt the solder but not so hot that it will burn the PCB (not right away at least). The goal of soldering isn't to melt the solder directly though, it's to heat your joint so that the solder flows into it, without heating everything around the joint too much. So you can definitely adjust to what feels right for you.

-

Cool. That's a good starting point. I solder audio and other types of connectors all the time, but never to a PCB. Ill start there and see how it feels. Also I read alot of people on here recommending to practice on a junk board first, so thats what I'll do. Thank you.

-

You can also watch Rob's(Madcow) youtube video's ....and see how he solders. He dose it quickly not to heat up the sound board or LED board...course he has had lots of practice and he makes it look easy...but its not that hard once you get the hang of it. Also pre-tin your wires..(as you will hear him say in his video's many times)...not only dose it prevents them from fraying while soldering, but it also make them bond to the solder joint faster so you don't have to hold the iron there to long....and its just a cleaner look...imo

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote

Bookmarks