-

PVC Curved Hilt + TCSS parts

PVC Curved Hilt + TCSS parts

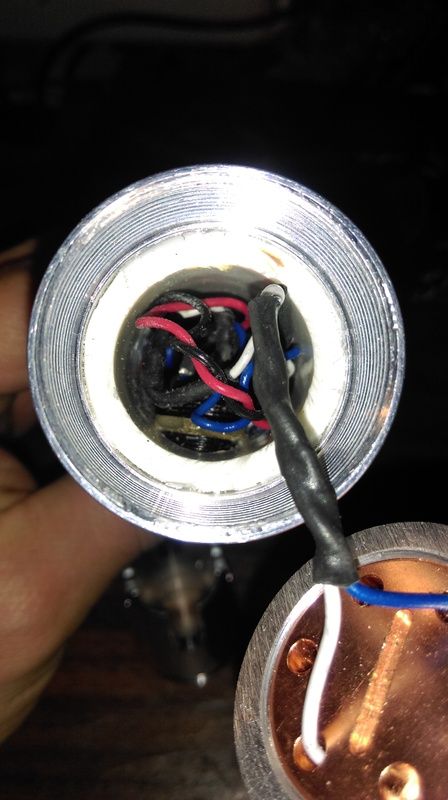

After making 9 PVC sabers for my kids and nieces and nephews then a MHS saber for myself, my wife wants me to make her a curved hilt saber for her. I have the curved hilt body made, but I want to make it nicer by using parts from TCSS on the ends. Has anyone had success in matching parts up to 1"ID PVC? The OD is 1.31". Here is a pic of what I am working with:

I was thinking about using the 1.25" sink tube adapter (if it's ever back in stock) and trimming the ID to fit over the PVC.

-

-

Jedi Knight

Yes, I have adapted MHS parts to PVC pipe. Many times. It is FAR, FAR easier to trim down the PVC pipe since it is a softer material and there is a LOT of wall thickness. Then use the MHS-to-sinktube adapter to couple MHS parts to the PVC pipe.

-

I ordered some 3 inch double female extensions to fit on both ends. I am thinking with a little filing, some heat, and a little Dark side persuasion, I will be able to get them to fit. I will secure it with screws and, depending on how it looks, I may do a leather wrap to conceal the joints. I will post again with the results hopefully by the weekend.

A side note: I have an 18650 battery holder and it slides freely all the way through the curve.

-

Jedi Knight

If you don't want to go with the leather wrap to hide the step between the MHS parts and the PVC pipe, you could use what they sell at Ace Hardware as "plumbers putty". It comes in a plastic tube, runs about $10, and is a 2-part epoxy you knead together then apply. It sticks to anything, and once cured, you can file it, sand it drill it, paint it, etc. I've made sculpted Sith sabers out of nothing more than PVC pipe and that plumber's putty. Just giving you another option to try if you want. Example:

Attachment 12571

-

I know what you are talking about. I've used it on other stuff before. Thanks for the reminder.

-

Originally Posted by

Jonitus

That's pretty boss! Is that supposed to be a rancor tooth?

-

Jedi Knight

I think that's what I was going for initially. I haven't worked on that saber in a couple of years, so I'm not clear of memory exactly what I intended for it. I don't want to finish it, but I don't want to throw it away either, so it just kind of takes up space in my packrat collection LOL.

-

I'll be happy to finish it.

-

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote

Bookmarks