so I have 3 sabers I need done by premiere time. so I'm doing a little build log. Nothing too fancy here but nice none the less.

2 are having Nanos

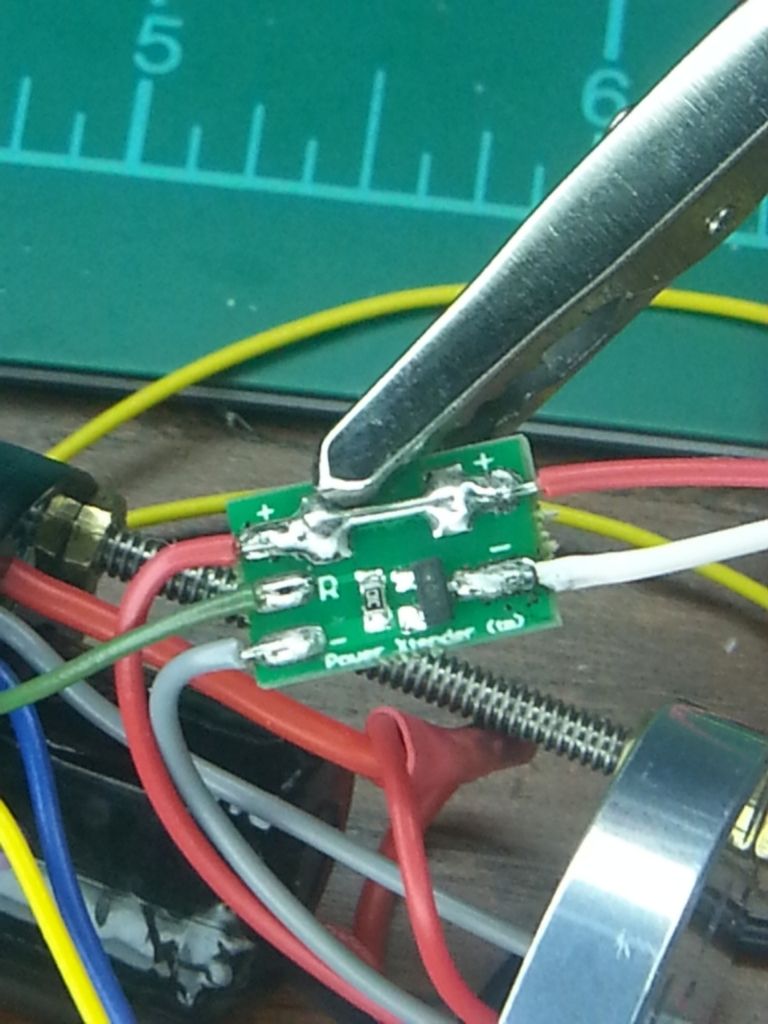

board tinned

Pex tinned

board soldered

Pex soldered

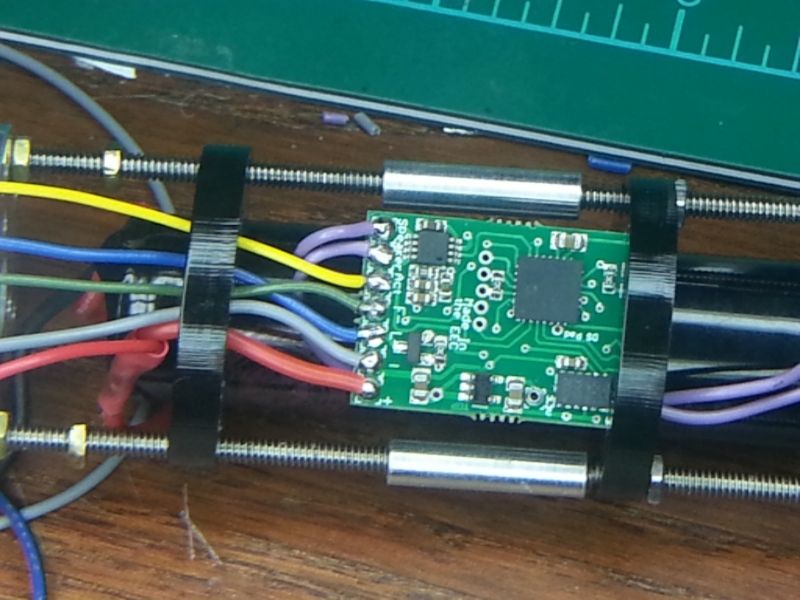

board in chassis

I did another one only difference is that saber has a power on indicator

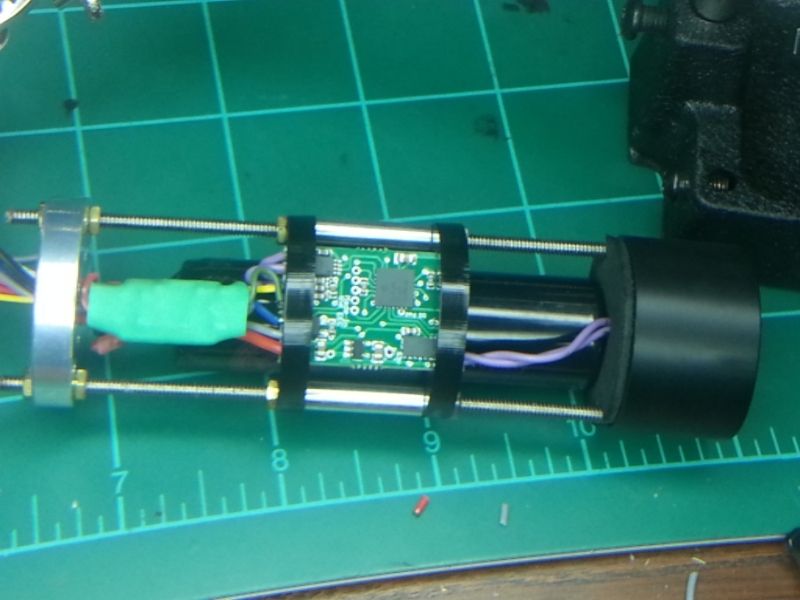

the two lower sections for the Nano sabers. Haven't started the Prizm saber yet, will start that one next week.

Also a quick question guys. on the rubber grips you see on one of the hilts how well does that tape hold? I'm a feel a little suspect of its longevity.

Reply With Quote

Reply With Quote

Bookmarks