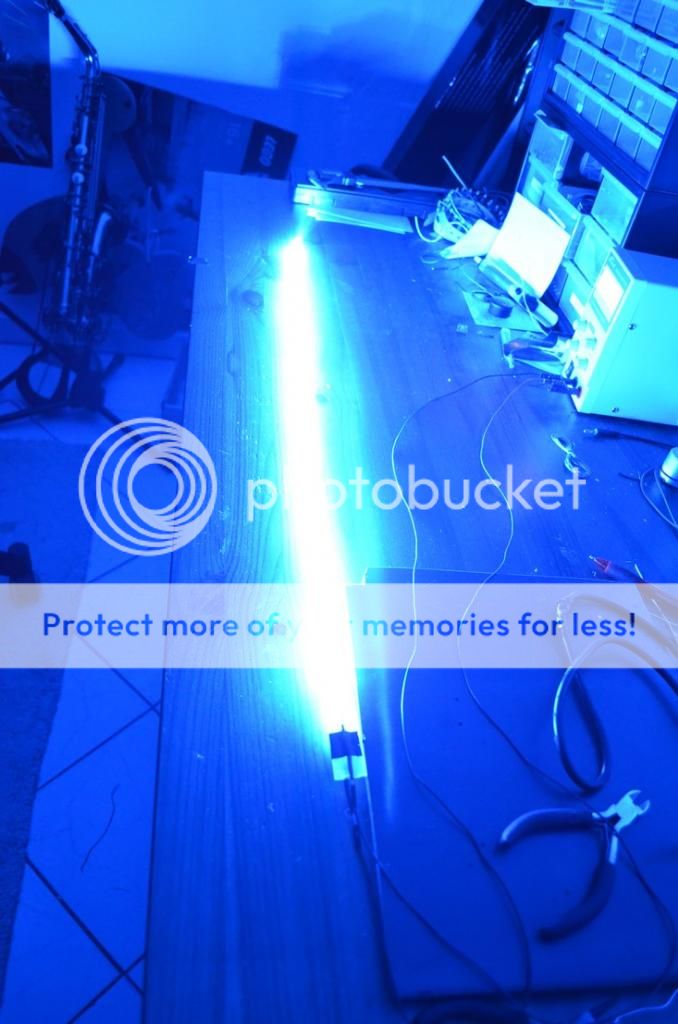

So finally I decided to follow the instructions of accomplished masters and build my own LED string lightsaber(blade). I've got a lot of invaluable hints and inspirations from this forum and could not wait to start. I would like to share my progress (still working on it), less in order to reinvent the wheel (there are a lot of beautiful LED string blades out there), but to get more valuable hints from you as I go along.

I long pondered upon how to link those LEDs together, until I stumbled upon a good description in Erv's CF-LS documentation, honour where honour is due, thanks for Makoto-San and SlothFurnace for their tutorial on how to build the "arm buddies" type LED string. I also found a similar link here: http://www.waynesthisandthat.com/lightsaber.html

I'd been researching the topic of how to modify the LED to get the most out of the LED string, including the different methods to shear off the dome for more even light emission radially. At the end I decided to go for a string using 5mm LED's as they are, I figured that if I was not satisfied with the results, I could still try again with a string of modified bulbs.

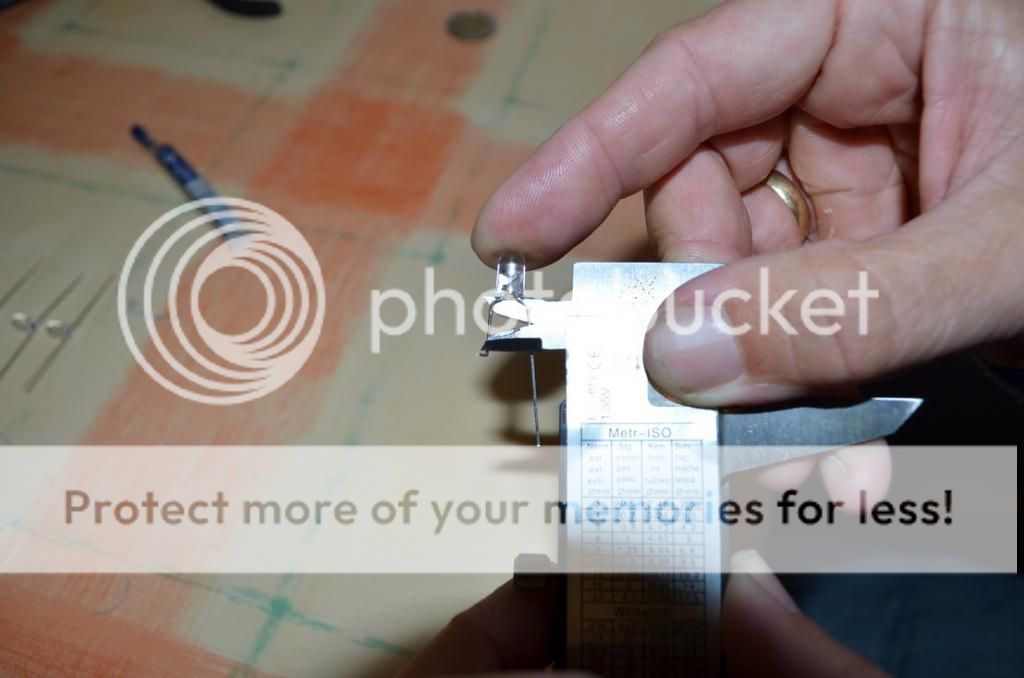

But how to achieve a uniform and consistent LED string? At the beginning I had no idea what tools to use to bend the legs so that the process can be reproduced for >80 LEDs. I made a lot of measurements and came to the conclusion that the distance between the LED legs should be 6mm, bent at the lower end 10mm below the bottom of the LED. But how to make that 6mm and that 10mm bents consistent?

It's only through purest luck ... ehem ... there is no such thing as luck, obviously the Force wanted me to find that pencil lead holder, whose shorter side just measured 6...

Next step was to find a good jig to bend the straddled legs agt exactly 10mm. After some looking around over my workbench the Force made me gaze at my vernier caliper. I might have been in a Force induced trance, becaese I do not recall any more how I found out the way to bent the legs with the caliper, enough to say that at the end I used the inside small jaws to open them at 10mm and put the legs of the LED right through the jaws and bend them at the other side like this:

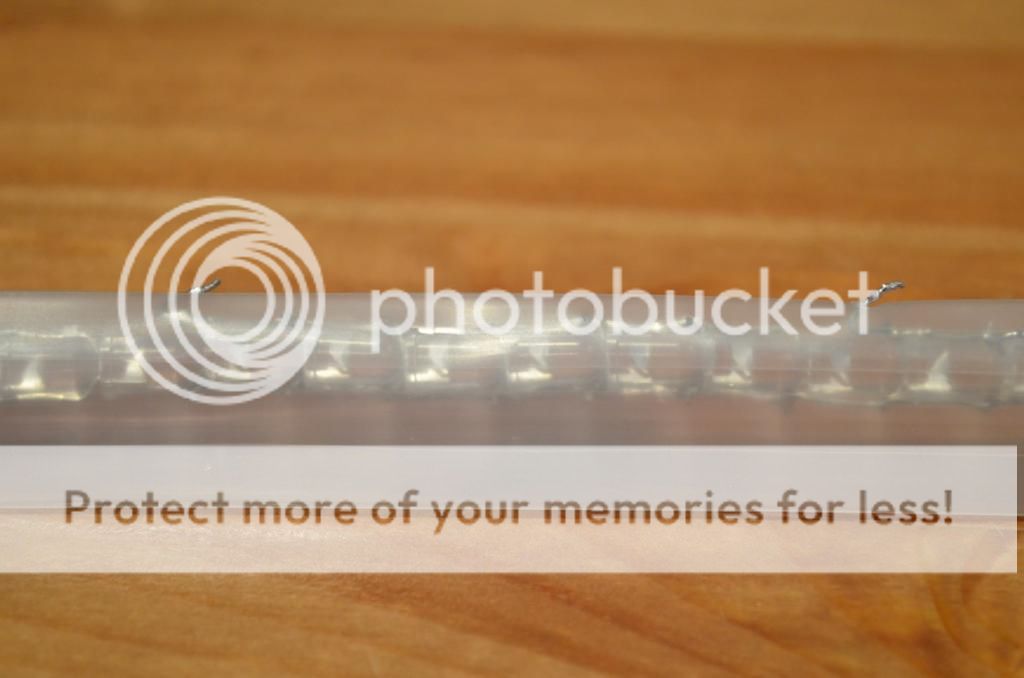

After this I just followed the lighted part of the Masters mentioned above to link the bulbs together:

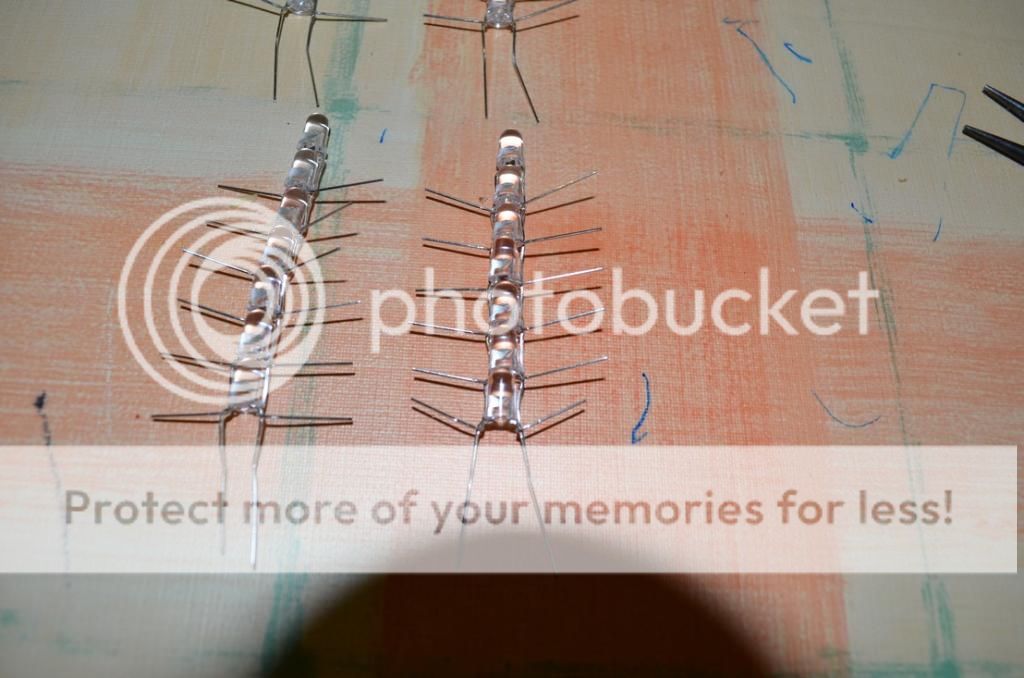

With tweezers I bent the linked legs to the sides to lock the LEDs in place.

Finally I had my small seqments, now it was time to think about how I was going to wire them... more to come as I progress.

Reply With Quote

Reply With Quote

Bookmarks