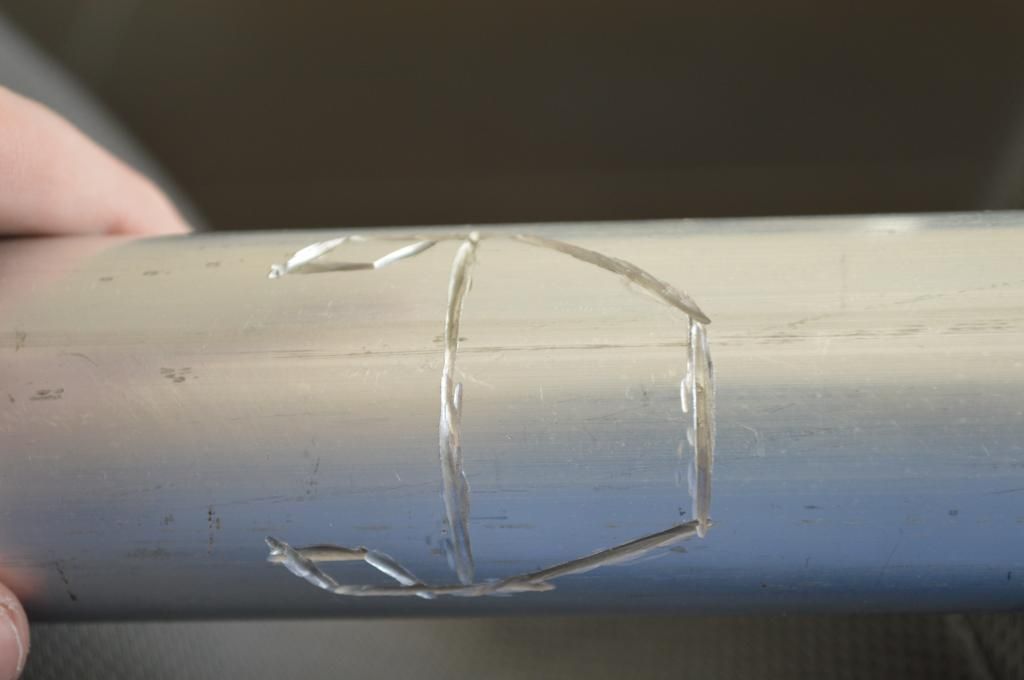

That's a good point on mounting to the underlay, I'm just super reluctant to fiddle with the MHS parts too much because they are so hard to replace here in Aus, lol (If I stuff something up). If I can practice enough on some other parts, I may feel better about it, I sense a lot of trial and error in the distance.

I'm in the process of asking Arryck what he did, because he is currently going through a build using a mesh.

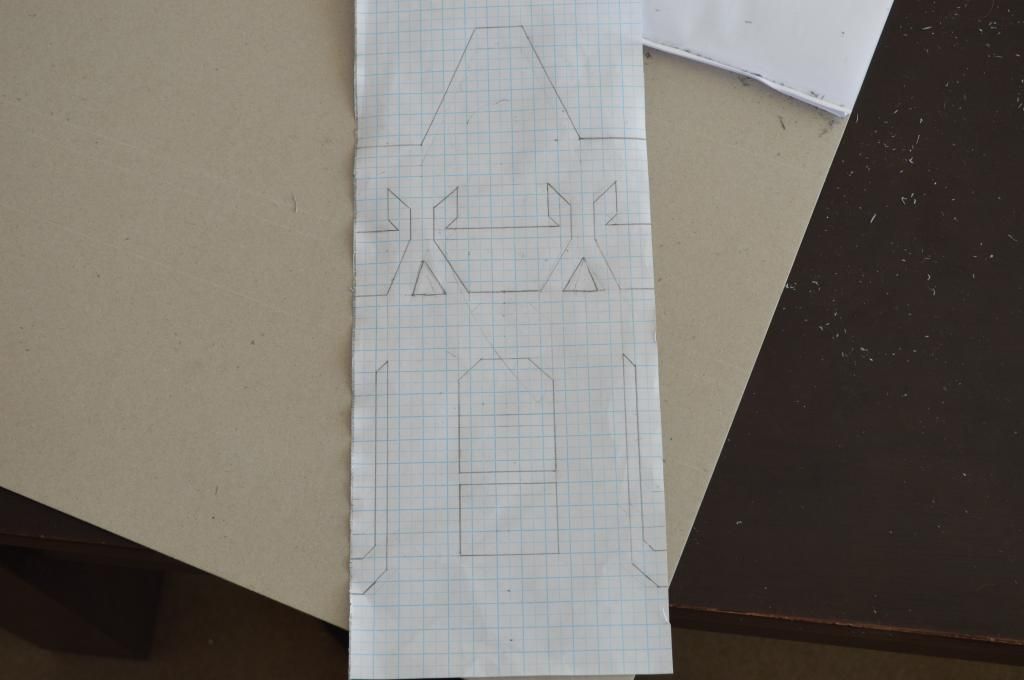

EDIT: FJK one of the plans was to mount it into the underside of the shroud, Iv'e even had he thought of mounting it in the middle of the triangle cut as well, if that makes sense.

Reply With Quote

Reply With Quote

Bookmarks