Not having much luck today on the FX boards so I turn to the people at TCSS. Iv'e been looking at etching today and ended up liking the idea of acid etching. In terms of understanding the process, I found some good tutorials (Goodman's in particular), but he used free hand drawing for the template, people will tend to use adhesive printer paper now right? Just don't want to try freehand the design I had in mind.

Just so I'm understanding how it works I was planning on drawing the design up on my computer if I can (or scan a hand drawn), print it on printer paper, use an iron or something to transfer the image, make sure the resist is applied properly, and then throw the tube into the acid.

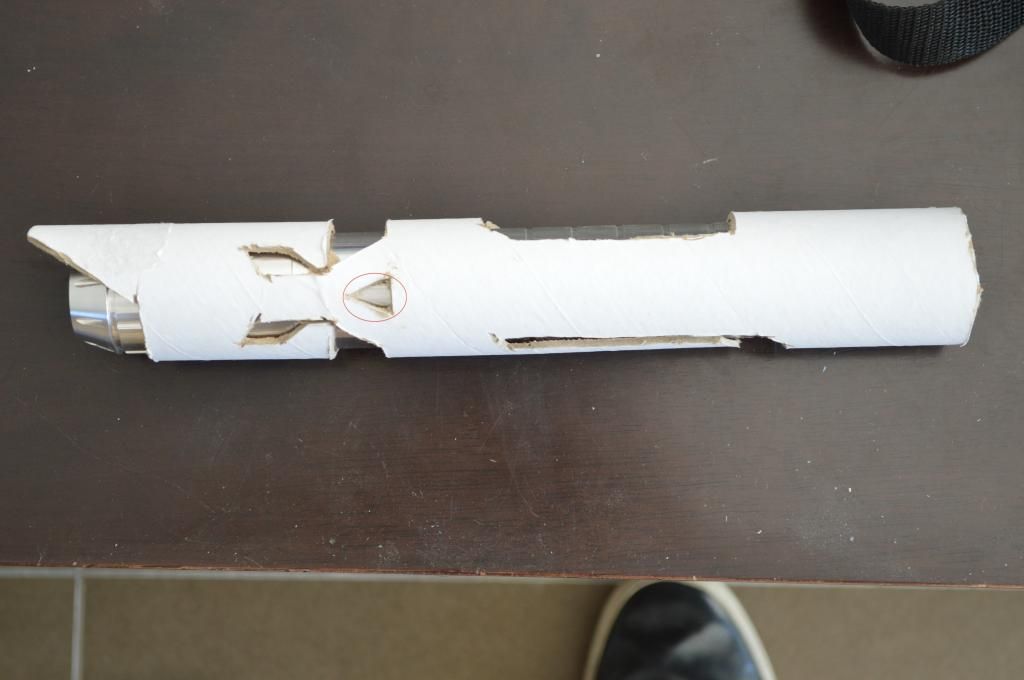

Here's what I had in mind for the etching:-

-First off I'm thinking of having some irish style vine etching along the Y shape of the overlay:

-Something similar to this but without the clovers so that the design is still subtle and not too recognisable:

I'm hoping that cutting out the overlay first with the dremel won't make applying the resist too difficult (feel free to share any thoughts on that).

Right now i'm hoping with my questions in mind as well, that the main difficulty now should be just making sure that the image would transfer easily enough.

I have a while to think about all this, while I'm away from my tools and what I had down so far, just thought I might get my head around other things I had been planning.

Thanks guys

Reply With Quote

Reply With Quote

Bookmarks