hello everyone,

While I wait to get my Starkiller parts back from being anodized I decided to start on my next saber...Satele Shan's double bladed saber from the old republic trailers. I only have two and a half months before I graduate, which means I'll lose my shop access. So basically I need to get this done quick, not like the year and a half it took to do my starkiller.

first-off I need to thank master slothfurnace for getting me started, and for making an awesome saber that I wanted so bad I just had to make one myself. His build can be found here...though I'm sure everyone's seen it:

http://slothfurnace.com/sabers/TORConsular_01.html

The original saber:

Anyways...here are my preliminary models:

I was very excited to see Tim release the blade holder for this. That was really the catalyst for me to actually start this because without it I'm not sure I'd be able to finish in such a short amount of time. Unfortunately, the MHS threads didn't really fit with what I had planned...so OFF WITH THEIR THREADS!!!

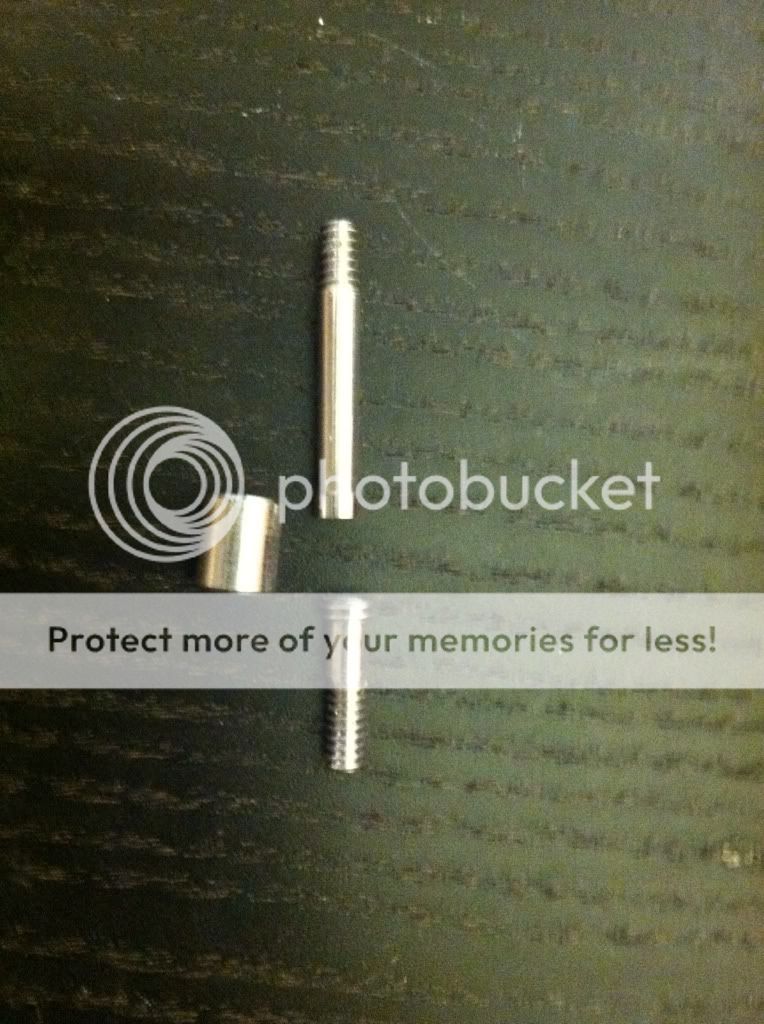

This made me sad cuz it's a beautiful part so I hate to do that to a perfectly good part. But it had to be done I suppose. To attach it to the main hilt I designed an adapter that will pass through the blade holder and screw into an adapter in the hilt...like so: (the skinny part will be threaded obviously)

Next I milled out the slots for the fins. To line it up, I put a flat plate tangent to the slot on the side, which is 180 degrees from the fin slot. This actually worked out really well for me. The three slots look 120 degrees apart, which was the goal.

Next I drilled/tapped 4-40 holes in the center of each milled slot. This is how I knew my technique for lining the slots up worked. I did all three holes at once after all the slots were milled without rotating the part...and they all seemed to end up in the middle of their respective slot...if that makes sense

Next I just threaded in some 4-40 set screws. These are basically just gonna be pegs that will fit into some clearance holes I'll drill into the fins. That'll keep them on the blade holder, along with the tension from the rods (which I plan to left-hand-thread the back)

Two blade holders done!

For the switches...I can't decide between the new short SPST ring switch, the long DPDT ring swith (for the price/finish), or the long DPDT dot switch like sloth used.

http://www.thecustomsabershop.com/16...itch-P703.aspx

http://www.thecustomsabershop.com/16...itch-P435.aspx

http://www.thecustomsabershop.com/16...itch-P436.aspx

I think I still like the dots the best. Theoretically I could buy some and if I don't like them I could switch them out really easily with quick disconnects. We'll see I suppose

wow, sorry that was so long haha Thanks for reading this far

EDIT: I forgot to mention the fins will be cut on a waterjet machine which should save me a ton of time

Reply With Quote

Reply With Quote

Bookmarks