Fair enough, Skott lol...

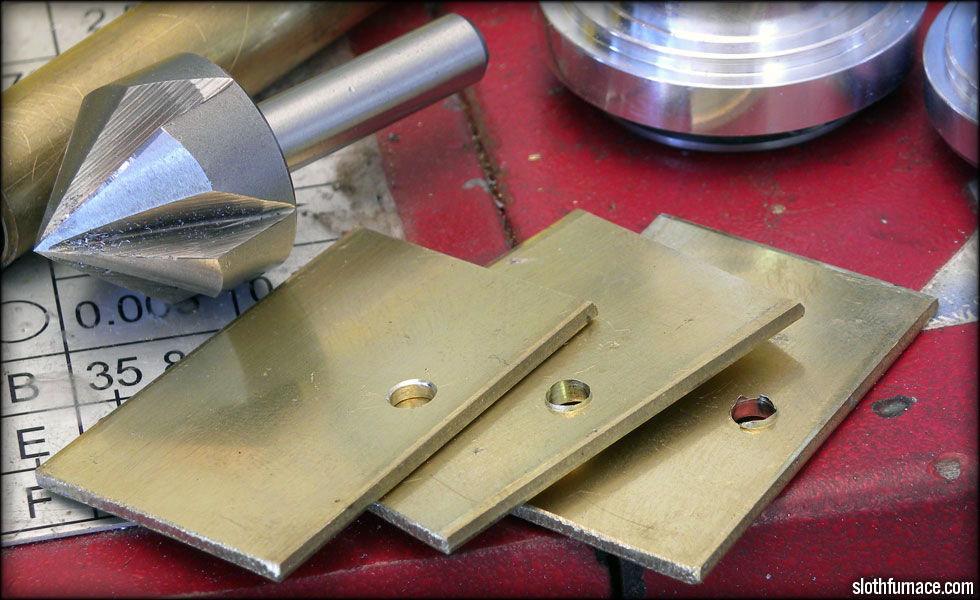

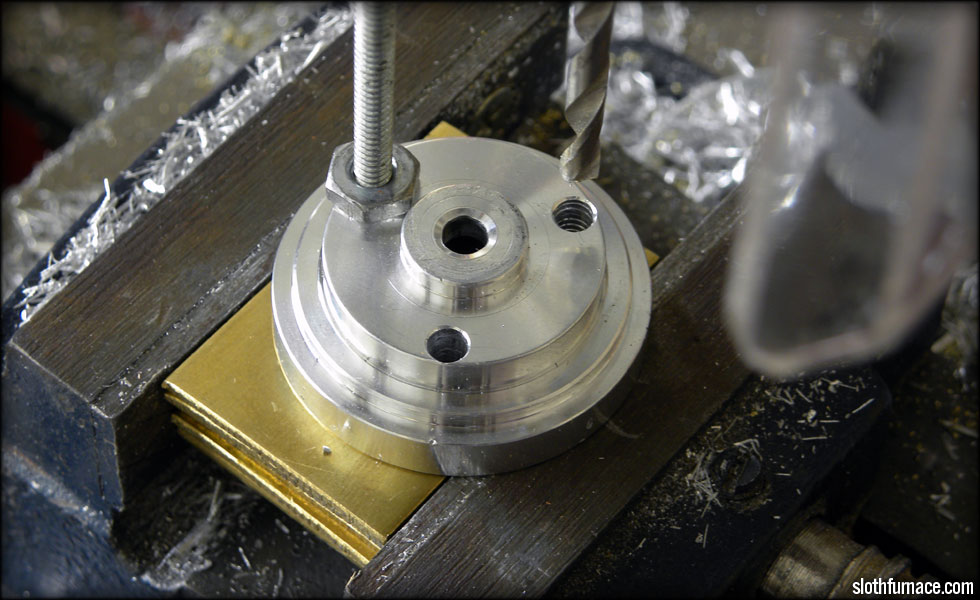

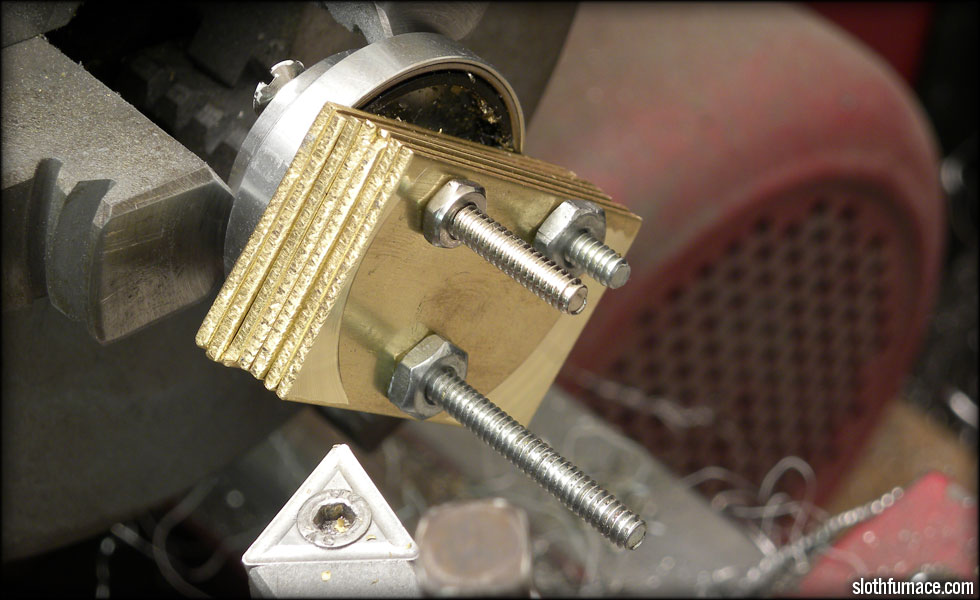

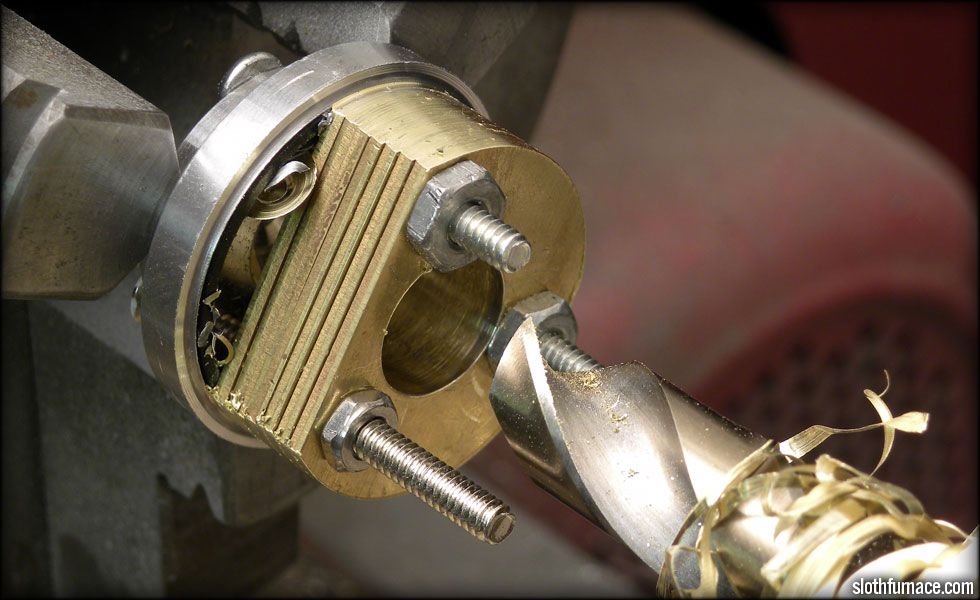

Here I have sectioned off some thick brass plate for the radiator section. This saber will have much thicker plate here to go with the "beefyness" of this saber.

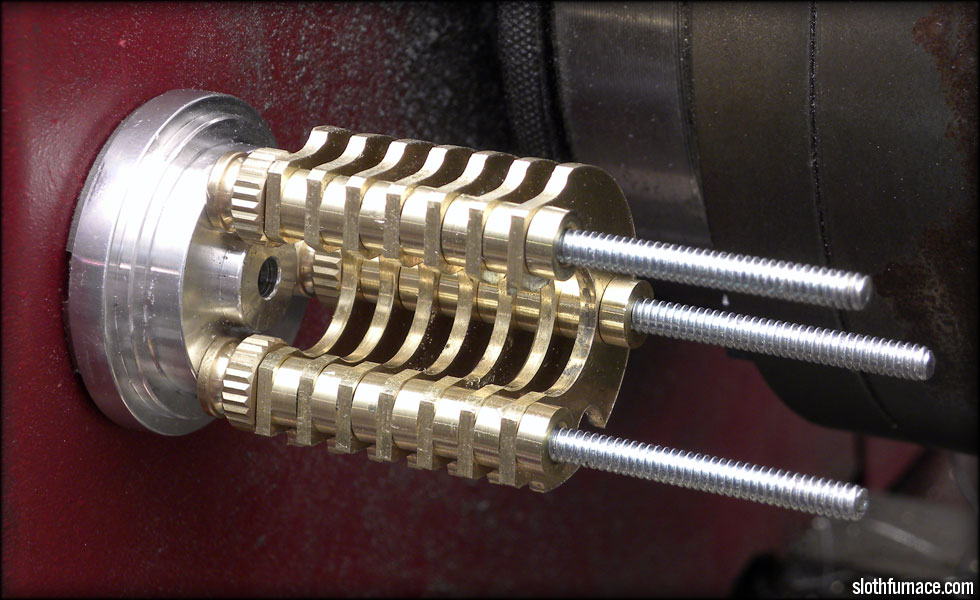

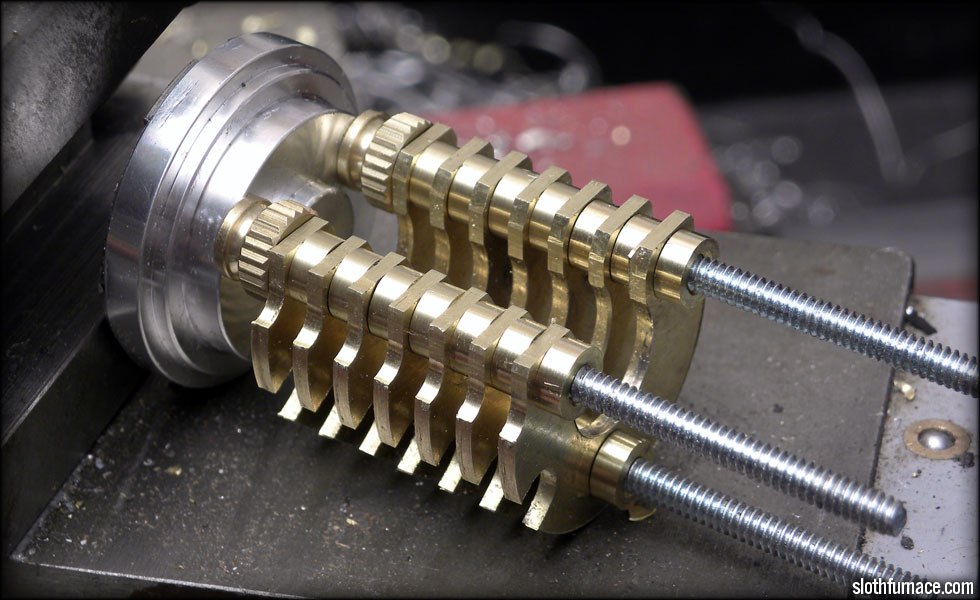

Laying out the parts, sizing up what I have, and what I have left to rough in. I will have enough room for what I want to do, I think. This is a Heiland flash gun, with more or less "correct" coin knurling on the endcap. I have a Parks MPP replica coming to actually use for this saber, but I wanted to get some idea of what I have to work with while waiting for that to come in. Also in this pic are four Harddrive motor casings, which I like to work with since they have perfectly spaced holes in them already.

Reply With Quote

Reply With Quote

Bookmarks