LOTS of work going on, almost not enough time to take pics...

almost.

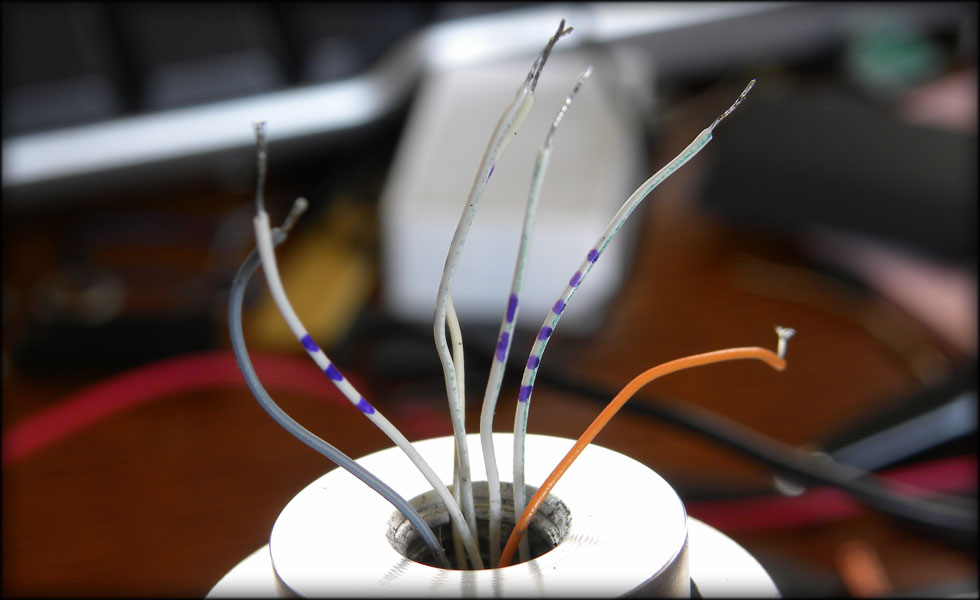

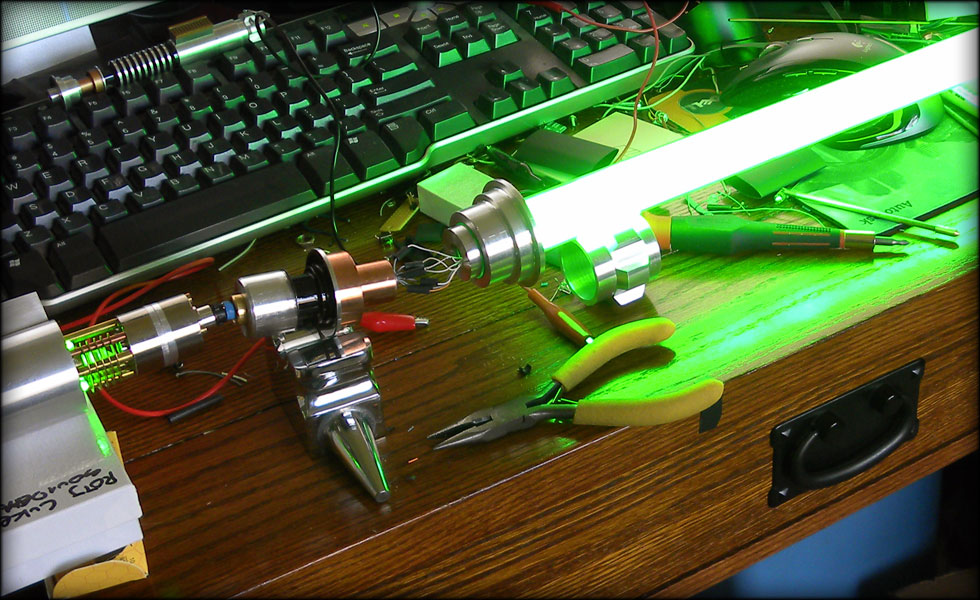

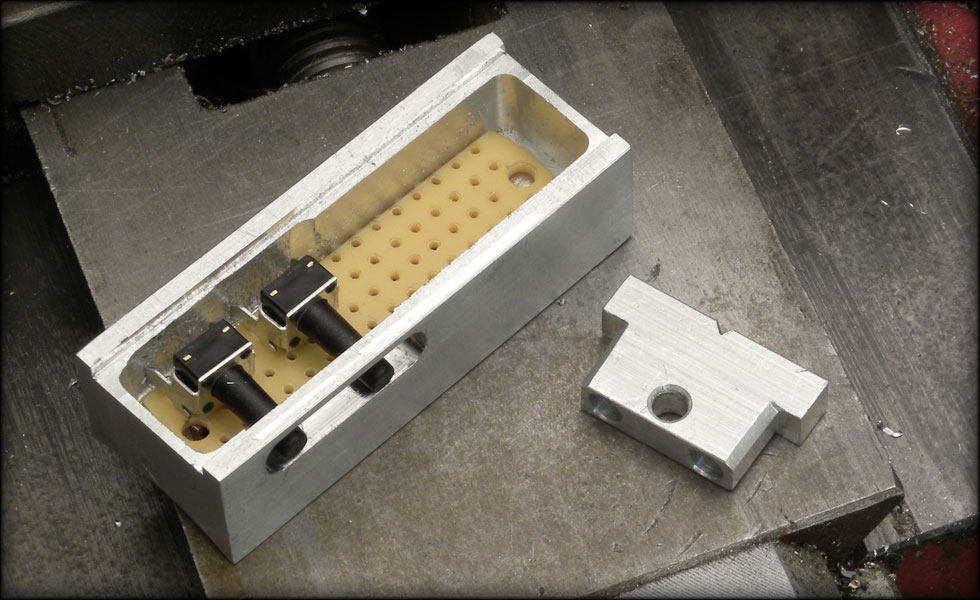

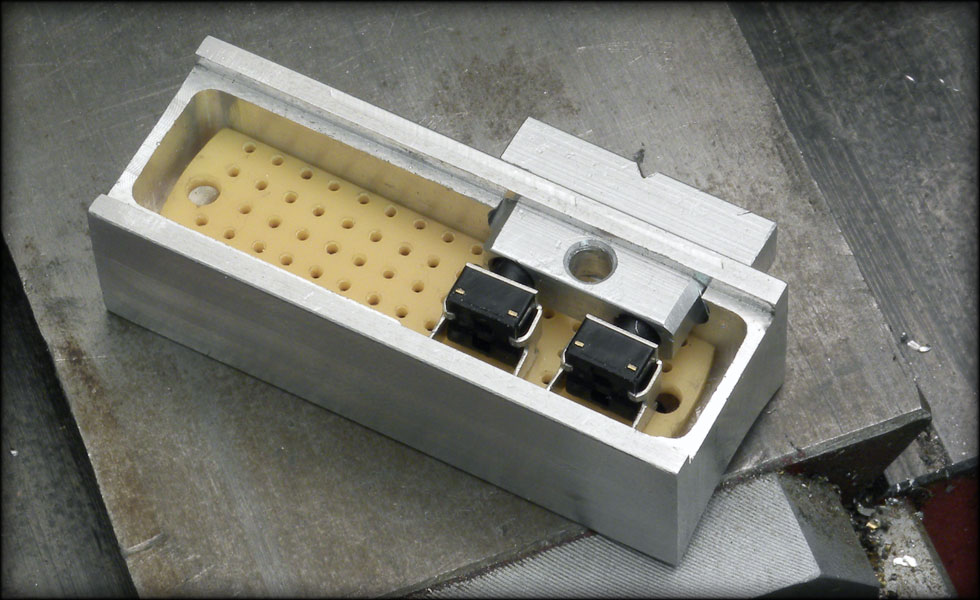

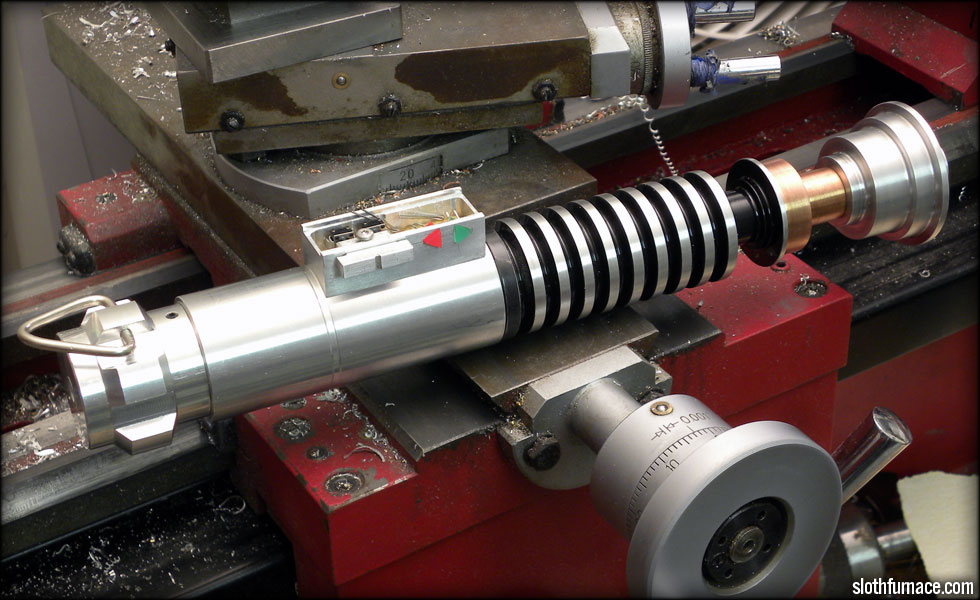

LOTS of wiring going on this week. Carefully and meticulously measuring, trimming fitting all the wiring and electronic components into the handle. Lots of tedious back and forth, measure twice, cut once, solder, heatshrink, sew the wires into place, etc. Also, got both neck pieces machined, and painted, once the enamel is cured, I'll sand off what needs to be silver, and drill for the setscrews that secure each neck piece into the hilt.

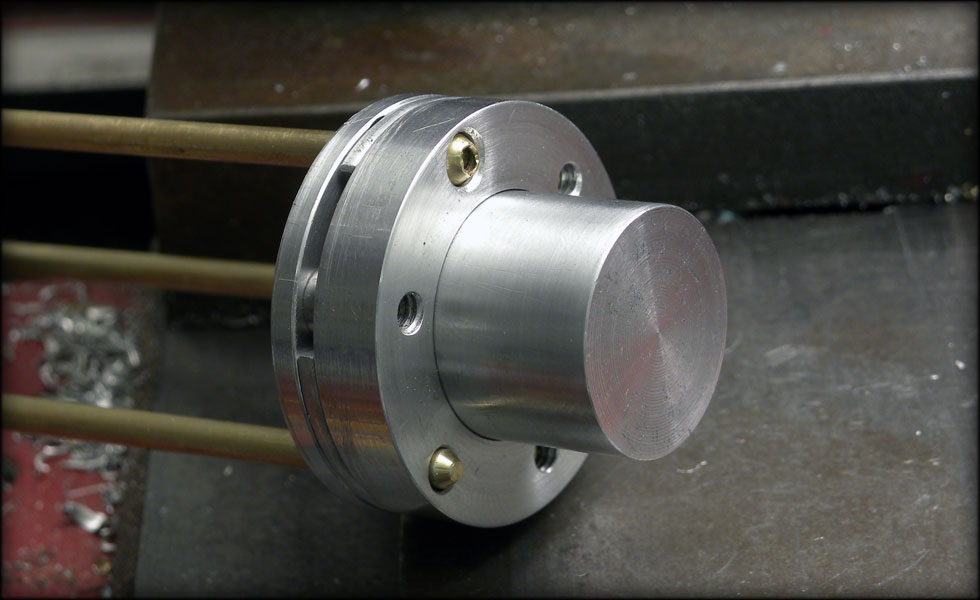

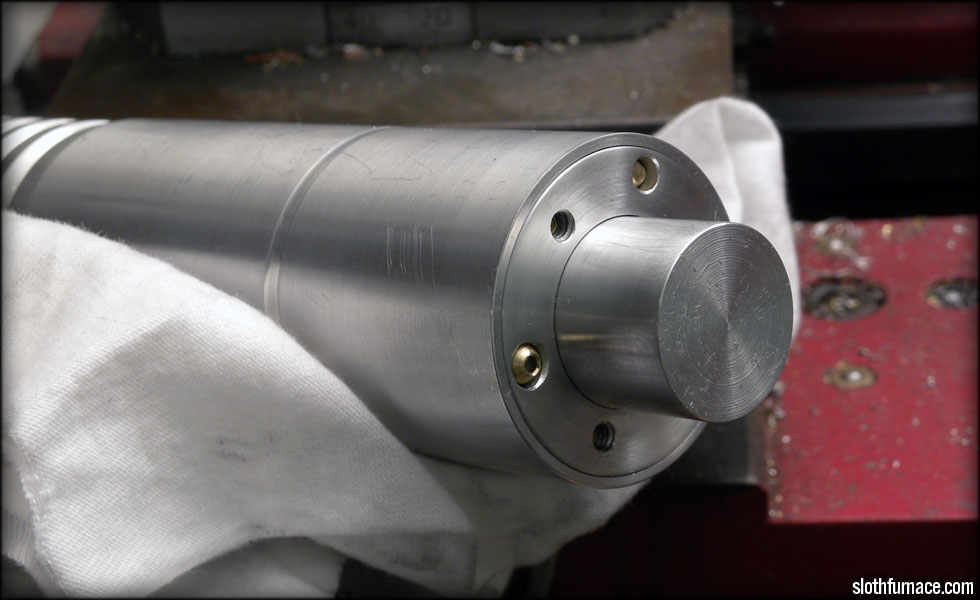

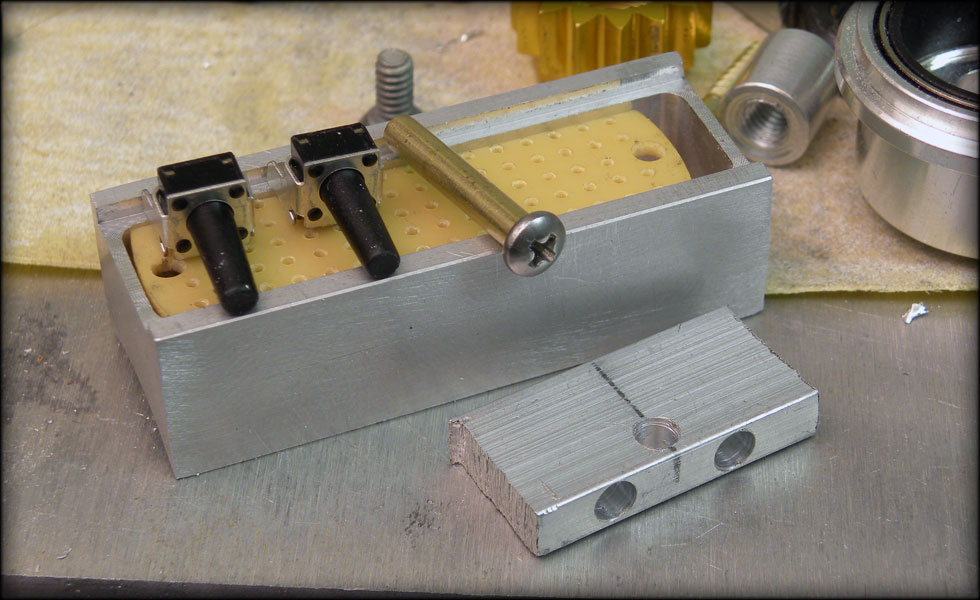

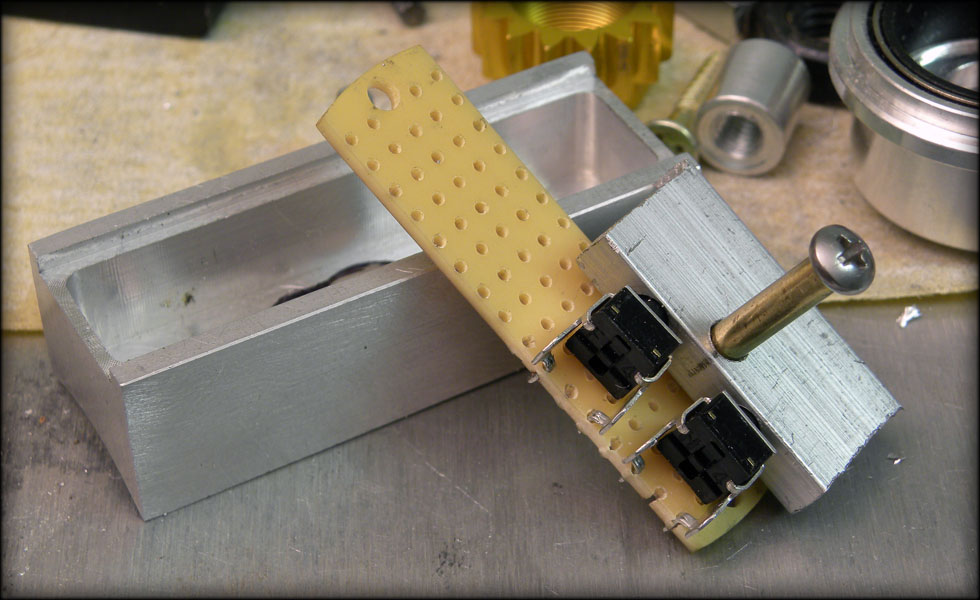

The wiring of the blade is pretty small work, this is before heatshrinking the wires and stuffing them into the blade neck.

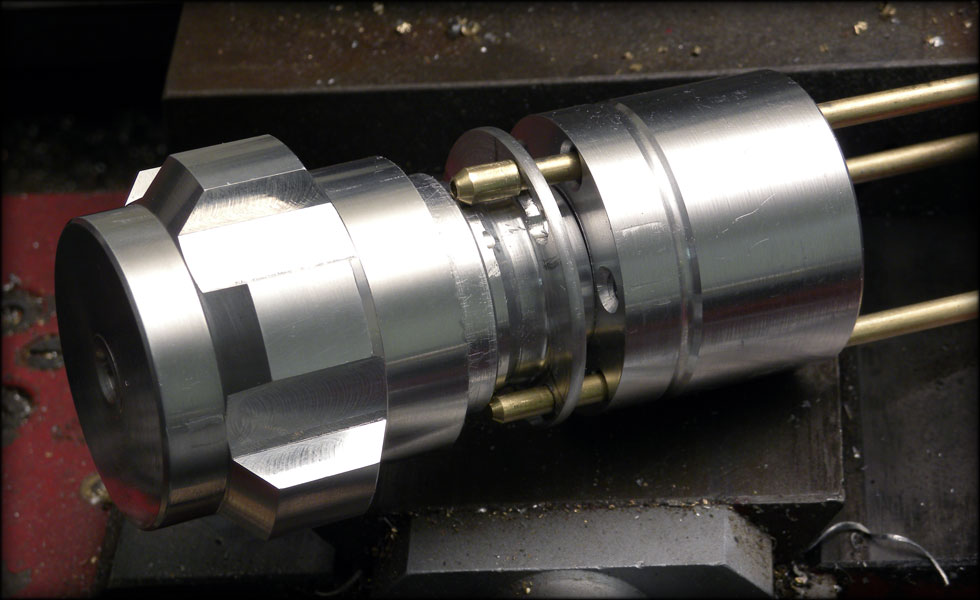

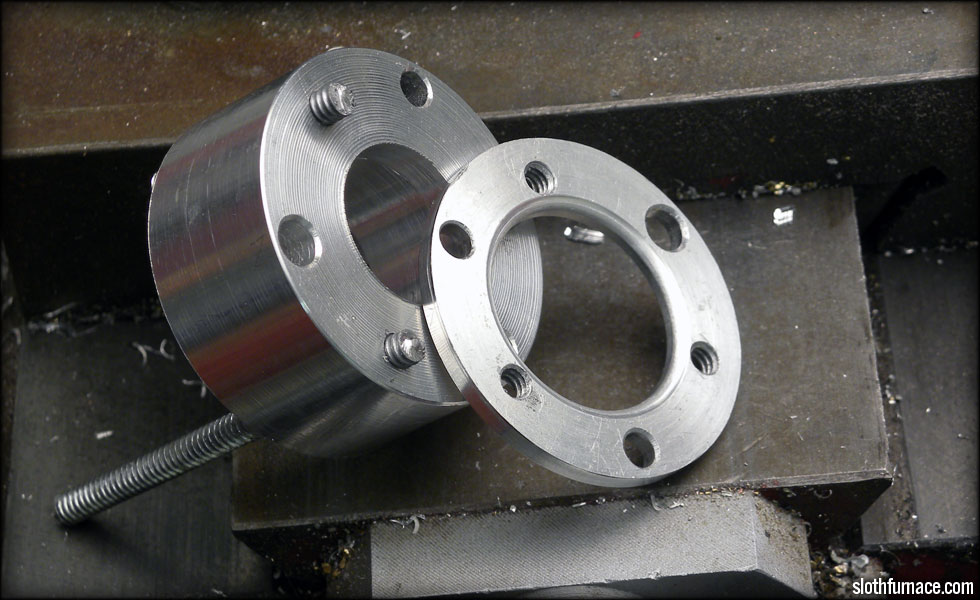

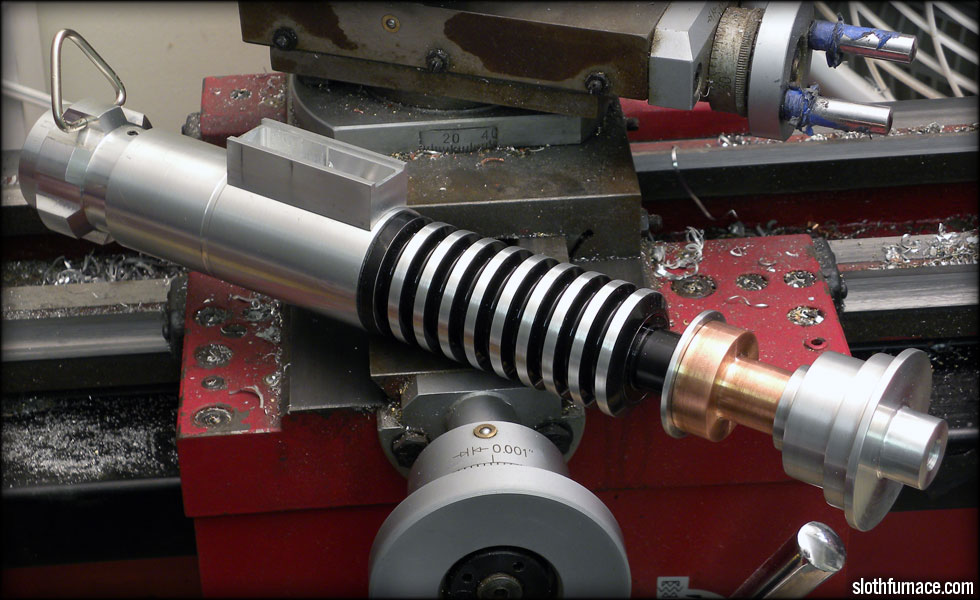

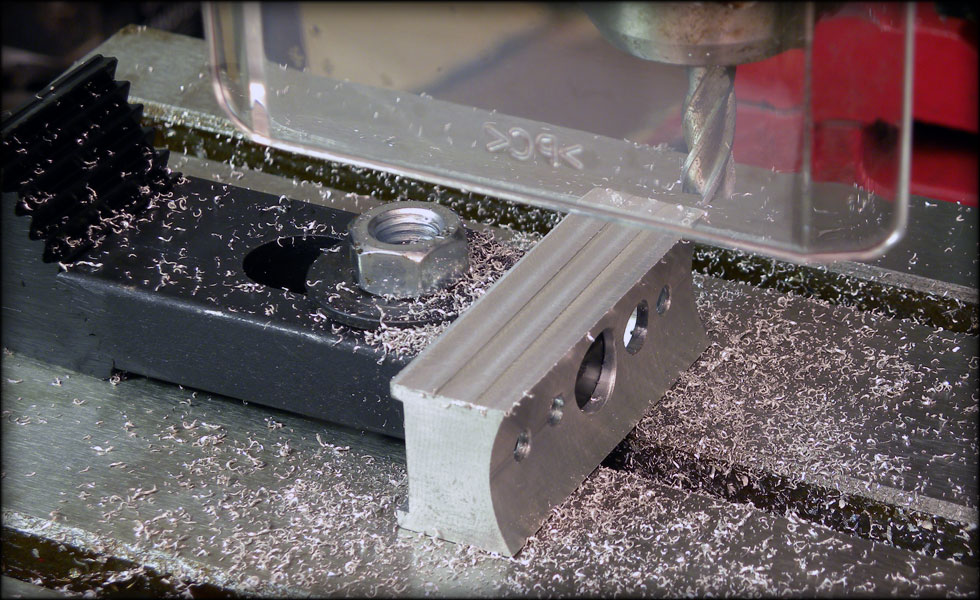

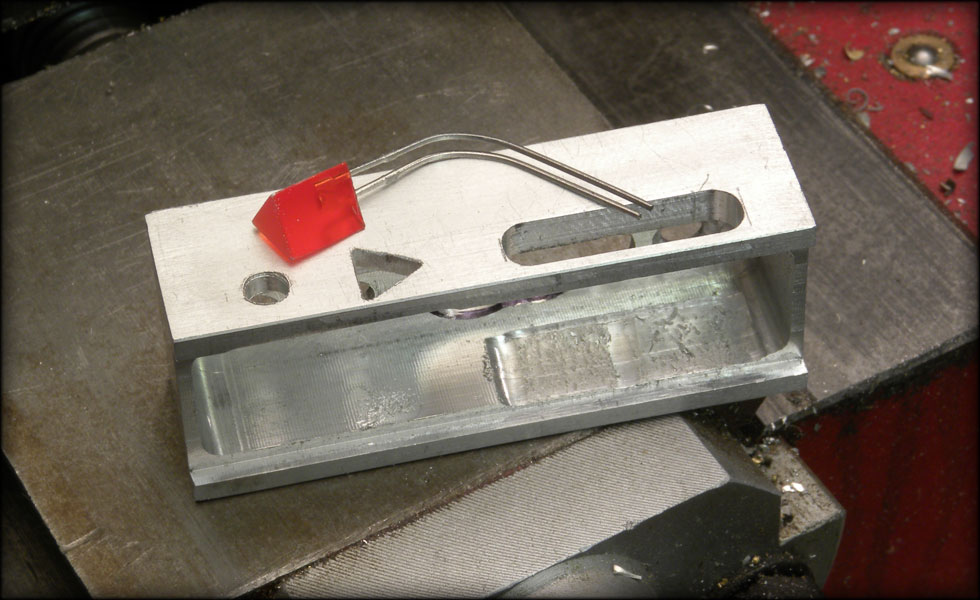

Here I am threading down through the template so all my bolt holes line up after I slice off my retainer plates.

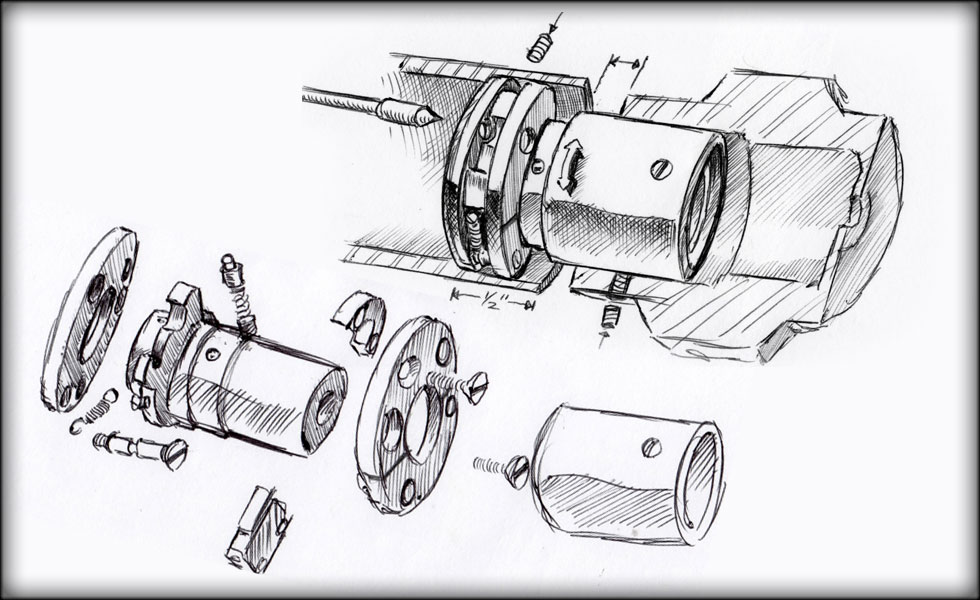

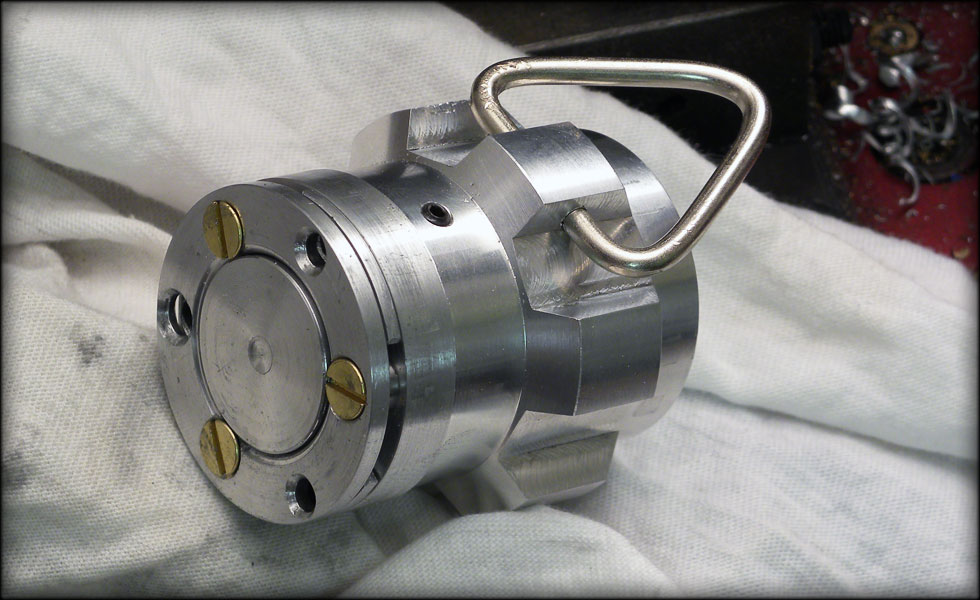

The template fits fine, and everything lines up. The latch twists clockwise to lock, letting the larger diameter plug pull against the slot to close it.

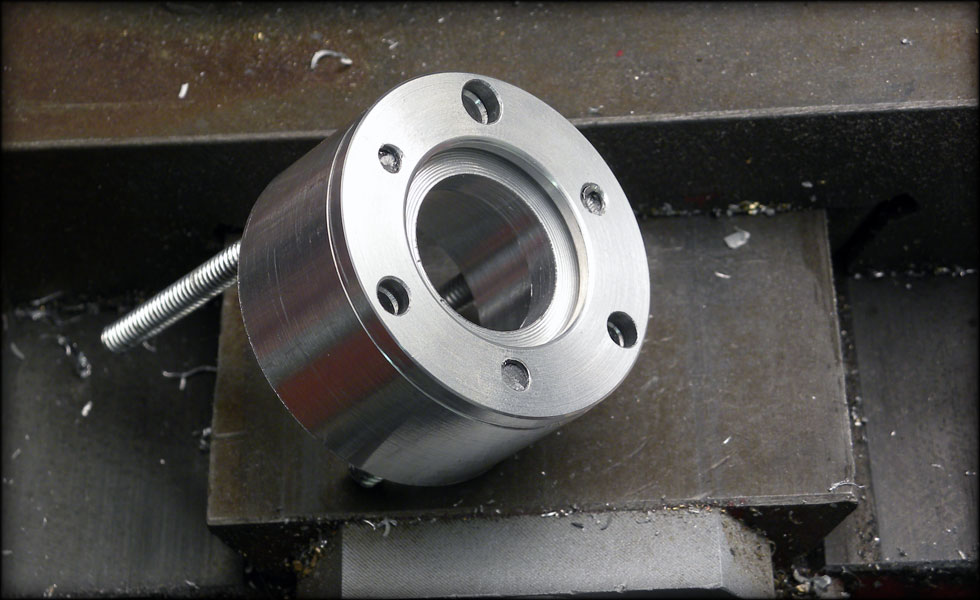

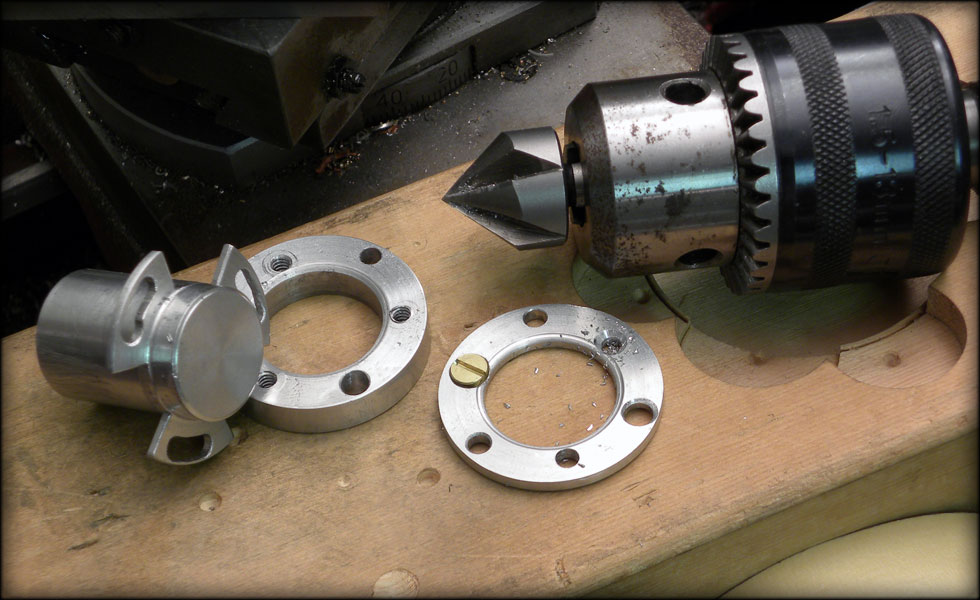

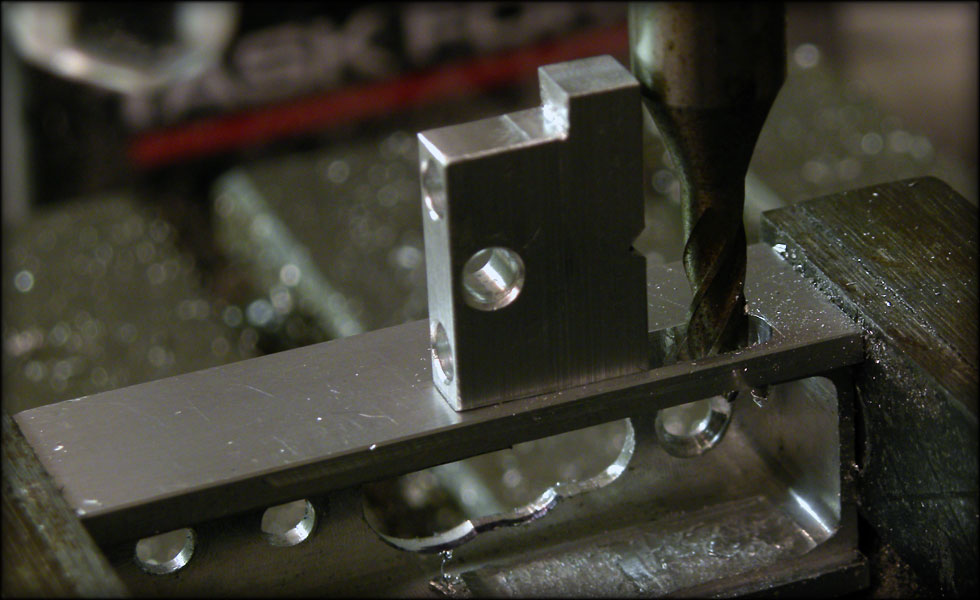

Here's the front retaining plate on the template after turning. I'll do the same for the back retainer plate.

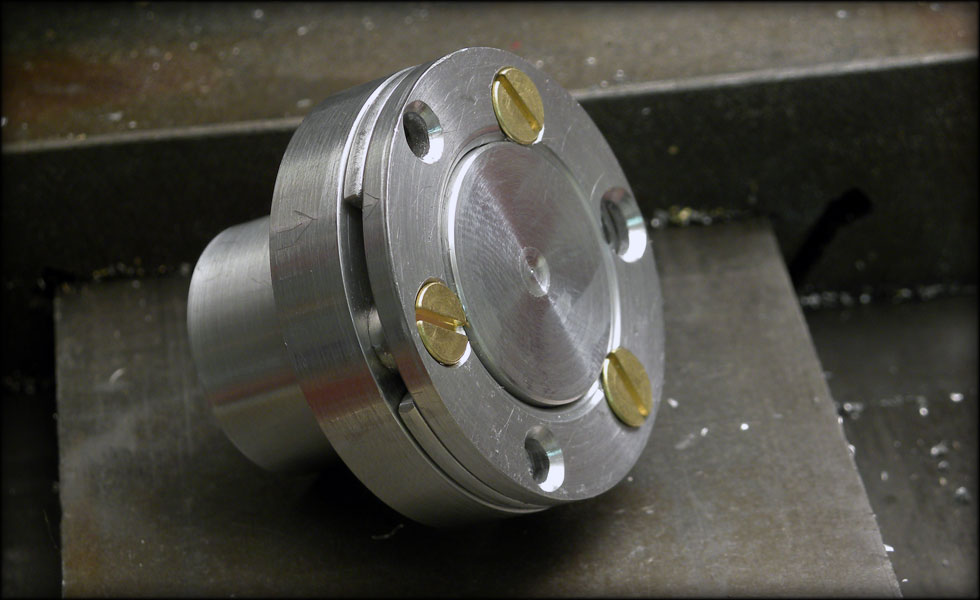

Here you see the final front retainer plate.. This method works pretty well as long as the threads all line up vertically enough to keep the work plate snug and tight to the template. I used some masking tape between the two while turning on the lathe to get the final smooth finish.

Reply With Quote

Reply With Quote

Bookmarks