Ok Folks, I caved.... (yes skott I know) I was going to wait until i had a gallery thread on this build before posting a Build Log... but I am just to excited and had to share!

This build will be privy to a couple of firsts (to the best of my knowledge) in custom sabers. First being the use of a Ventress soundboard in a fully custom saber, not a conversion. (Since I know this will come up.... I am well aware of the controversy over this board. Some hate it, some love it. Through speaker placement and hilt resonance I hope to cure the "angry bees" and have quality, low toned, Sith sound without the monkey gong. now enough of that discussion...)

Second being something I debuted the idea of back in November of last year.... A crystal chamber reveal using a clamp.

To give you a little background, and to help you understand the reason behind the name for this saber, I will explain how it all started. There were a couple of design cues that I wanted in the next saber I built.

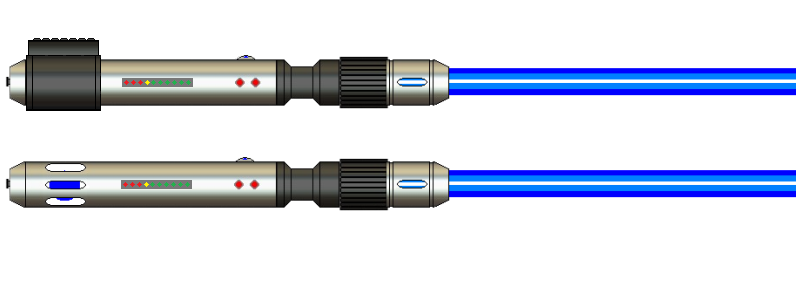

I had been wanting to do the C4 design mentioned earlier which, As you can see from this initial render, meant a crystal chamber. I also wanted the Gear section below the Blade Holder, I had not seen this recently and truly loved the idea aesthetically. The saber began life as a Jedi saber (i have made 3 so far, all Jedi) but then later became a Sith design.

The name Agony initially came about because no matter how I tried, i COULD NOT get the hilt below 14" using the Gear section and space for a crystal chamber, two design cues I was not willing to build the saber without. I personally prefer sabers to be 10-12" in length, anything over this feels too long and cumbersome to me. So I initially called this saber "Agony 14" in humorous reference to the agonizing i did, attempting to get everything i wanted to fit in anything under 15". The fact that it became a Sith saber and the back story later on, just fit perfectly.

The build has presented MANY challenges in the time that i have designed, and re-designed it. Adding to the reference of Agony. Soon the Saber included a PLI, another thing i simply could not live without.

Here you can see the Clamp reveal. Thanks goes to Skottsaber, and many others who have been my confidants on this build, and helped me hammer things out. Doing a Crystal Chamber presented me with a unique opportunity to design and implement a chassis! In designing the chassis, I realized that having the crystal chamber near the blade holder allowed for a few more easily executed parts of the build, wiring being one of them. This was about the time that the saber evolved into a Sith saber.

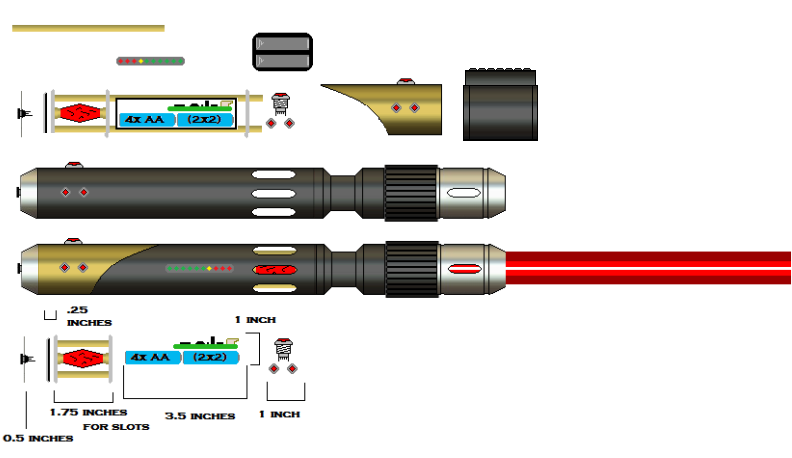

You can see from this render that a few things changed, namely the color, positioning of the chassis, crystal chamber and switch placement, with an addition of a Shroud piece. The shroud piece has yet to be decided upon, chrome or brass, and what design to put in it. (or if to do a completely different shroud all together.) You will also see some rough approximations for measurements, meant to help me design the electronics. At the present time, the Custom work on the Blade holder (the milled slots) may not happen, but I am gunning for it ; It all depends on funding and timing. Skott you have my paypal address

)

Now that you understand a little more about the background, (thanks for those that are still reading...)

ON TO THE BUILD LOG PICS!

(to help with the already long load for this thread, and due to the fact that not all images are within forum guidelines, i will make these click-able thumbnails.)

Firstly I had designed the internal Chassis system using 4 threaded rods to hold the batteries, soundboard, and PLI. I started out drilling a typical 1.25" OD steel Fender Washer to accept my 8/32 threaded rods.

I had previously purchased some brass tubing when making my crystal chamber proof of concept (found here) and planed on using this tubing in my build for Agony. A lot of people use rod such as this to cover the threaded rod, to make things look more sleek.

Here you can see the tubing on the rod, along with the knurled nut used for the Crystal Chamber.

This was done early on, before more problems came up and parts were even in hand. The Chassis system became redesigned due to space limitations. Shortly I was able to purchase some initial parts for the internals and Chassis, and was able to really measure things out and see them visually.

I am going to be using 4 AAA NiMH to power this build, and initially wanted to place them in a 4x configuration so as to save on length...

This ended up not working due to space constraints of the chassis and so I will be soldering them in a 2x2 configuration as shown in the render above.

Setting up the chassis the way I did, I could not connect the rods for the chassis to the pommel insert, and I did not want to attach it to the Pommel since i would have to pre-twist my wires for the recharge port that will be in the pommel. In order to do this, i needed a way to keep the pommel insert from "receding" back into the hilt. Especially since i was going to be plugging and un-plugging the kill key. I was able to engineer a solution!

I screwed the recharge port into the insert and measured everything, I would need to clip the port a bit, but everything should fit. That left me with the problem of getting 6 wires (4 for the port and 2 for the speaker) between the OD of the speaker and the inner wall of the Pommel. Any of you who have used a speaker anywhere like this know how difficult this can be, UNLESS... you modify the speaker....

You can see (may have to look closely at the full resolution photo) that I put 3 notches in the OD of the speaker. There is enough space for exactly 2, 26 gauge wires to sit side by side in each of the notches.

Next I clipped down the tabs on the port and used my sanding wheel to smooth them out (jagged metal + speaker + wires = BAD!)

I Placed the insert into the pommel with port screwed in, and then placed my speaker on top for a test fit. There is just enough room for wires between the port and speaekr!

I could not sleep one night and had sabers on the brainI came downstairs and started fiddling with my parts. (alright you guys, no wisecracks

) i knew the batteries in a 2x2 configuration would barely fit the board on top between my two threaded rods. How the HECK was I going to get my PLI secured with it? In frustration I set my PLI down against the batteries and rested my chin in my hands... then, blankly staring at the PLI inspiration struck! I quickly got out my measuring tape and measured the width of my batteries + the PLI. 1.243" !!!

It will JUST fit, with the heatshrink i'm using.

As you can see from the image above, i briefly played around with the idea of using some of the chrome housed accent LED's for the crystal mounts as I had seen some do. (I have since ordered a couple Makototsai v2 red LED's to use with the knurled nuts instead.)

The board and batteries JUST fit between the rods, I may not be able to use the brass tubing without modification, its that tight....

So I had my Washers somewhat drilled, at least for the main chassis section, but I needed to drill holes for my "switch section". As you can see from earlier pictures, i had my two rods on the "top" and "bottom" of my chassis, this would interfere with my AV switch, so I would have to run them differently. I first planned on running them on the two "sides" Like i was planning for my crystal chamber, but realized this would interfere with my accent LED's. To remedy this i drilled out a couple holes a little higher on the washer, in order to "nestle" the switch in between them. This would also serve to hold the chassis in place from spinning in the saber.

And then....

DISASTER STRIKES!!!

I miss-mark my punch for the drill bit...

You can see the idea i was going for below

With all of this out of the way, i started fresh today, with some new washers. I started completely over. After everything was drilled and tapped, I put it all together!

You can see here my idea for the Crystal Chamber

As well as the main chassis section (the rods will be trimmed later)

Here is cross view of how the switch will sit as mentioned earlier

And a couple more shots

Finally, I had to make sure that the two rods that held the crystal chamber section would be close enough together to allow my Main LED wires to pass through the choke section. I had a choke 3 sitting around from another build and tested to see how it would fit with the ID

Success!

The choke will sit against the "front" washer of the chassis, like this:

so it is important that everything be snug.

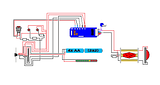

This is where I am at so far. I should receive my 8" DF and Choke from Tim on Monday, which will allow me to test fit everything in order to get measurements exact. At that point I will be able to start plotting everything out and begin the wiring of this monsterI want the accent led's, PLI, and AV to come on when the kill plug is pulled, and the crystal to sync with the main LED, so I will have to wire in the crystal chamber off a neg lead on the board, and the other accents straight off the pack. I am concerned about loosing current this way (read: run time) but have yet to decide how this will occur.

A couple extra points to make note of:

I noticed in one of Makototsai's threads that he uses clear packing tape for heatshrink, I picked up a roll to use at my local hardware store and will test it to see how heatshrink-able it is (should only be lightly so) and how feasible it is thickness-wise. Otherwise I will order some online. (Note, this is only for the board and batteries, all wires will be heatshrunk with normal materials)

Also, my MPP clamp for this build has to be shipped next week so should arrive by the weekend. I still have one more order to make when Blade holders come back in stock and then that should finish it all up.

Thanks again to Tim for this site and AMAZING customer experience, and Skottsaber for the HOURS of AGONY!Thanks to raf who did an amazing render of my saber which will be included in the Gallery thread as well, and thank you to all those who are following this. I am more excited that words can describe. Trust me, look at the length of this post!!!

Stay tuned... more to follow!

Reply With Quote

Reply With Quote

Bookmarks