sorry to beat a dead horse here..

but care to share how you turned down those brass nuts?

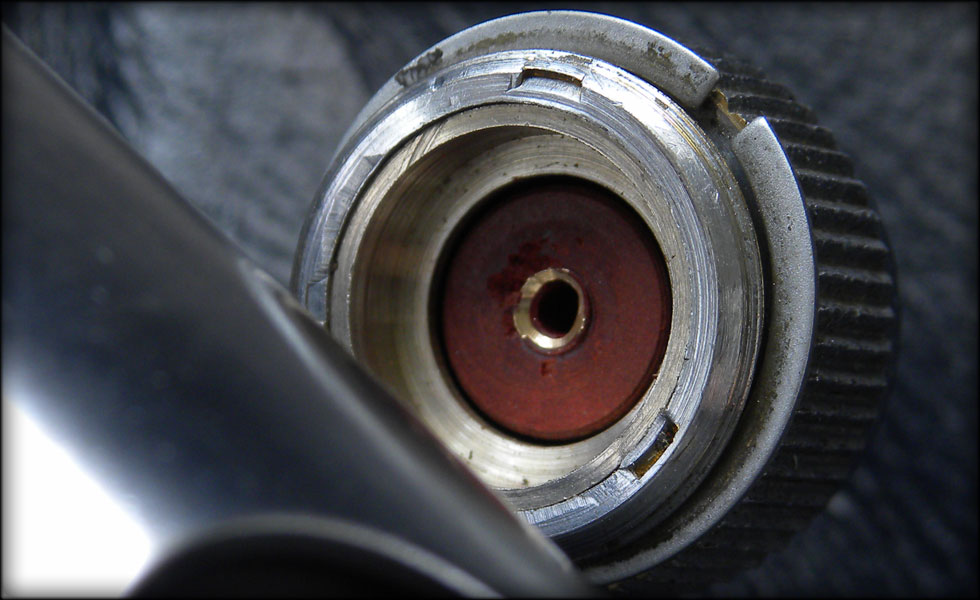

seems you have them on a threaded rod.. all tightened up and butted up to each other.. all the way up tot he chuck jaws.. (yes?)

on the other side though.. Im a bit stump'd.. I dont see a center in your tail stock or anything.. but more so a MT2/3 drill chuck in your TS?

what is it 'holding/clamping' on to though?

is that a sleeve over the treaded rod? so it spins freely inside?

Thanks

Reply With Quote

Reply With Quote

Bookmarks